(© Oct, 2007)

Air Technology Systems, Inc.

Compact CW Series Installation, Operation & Maintenance Manual

1-4

1.5 General Design

The Compact CW unit is housed in a steel frame type cabinet and is rated for indoor use. The exterior of the

cabinet is coated with a powder coat finish to protect against corrosion. Hinged doors are located in the front of the

cabinet for easy access to all components. Operator controls are conveniently located on the front of the cabinet.

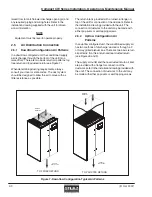

Figure 1 depicts a typical internal layout of a CCD-1800-CW unit and identifies the major components.

1.5.1

Electric Box Access

The electrical components are protected behind the

hinged access door located on the right side of the

unit. The access door is safety interlocked with the

main power service disconnect switch, (See Figure 4),

preventing the door from opening when the switch in

the “On” position. The switch must be turned “Off” to

gain access to the electrical components.

The service disconnect switch may be used to turn the

unit off for emergency shutdown or

during routine

maintenance. The handle of the switch may be locked

in the “Off” position to prevent unintended operation

.

1.5.2

Circuit Breakers / Motor Start Protectors

Individual overload protection is provided by circuit

breaker(s) and motor start protectors. These switches

must be manually re-set once the overload condition is

cleared.

1.5.3

Heaters (Optional)

The precision A/C unit incorporates heaters for re-heating

the supply air, as required to offset the sensible cooling of

the system during the dehumidification cycle, and for the

automatic heating mode. As a standard, electric resis-

tance heating elements are factory installed in the supply

airstream after the cooling coil to heat the supply air.

As an option, hot water re-heat may be selected. A hot

water heating coil is factory installed in the supply air

stream after the cooling coil to heat the supply air. A

valve is provided to control the flow of hot water through

the coil to maintain the correct re-heat temperature.

1.5.4

Coil(s)

The cooling and optional hot water re-heating coils are

aluminum finned/copper tube construction. The coils

are leak tested and cleaned before installation by the

factory.

1.5.5

Blower(s)

The unit is equipped with belt driven centrifugal

blower(s) with forward curved blades. The quantity of

blowers varies depending upon the capacity of the A/C

unit. Each blower is dynamically and statically

balanced to minimize vibration. The blower is con-

tained in a double-width, double-inlet housing. The

blower motor uses dual drive belts.

The blower motors are ODP industrial duty and utilize

permanently lubricated ball bearings. The motor is

mounted on an adjustable base for belt tensioning and

is furnished with an adjustable pitch sheave to change

the blower speed.

Figure 1- Typical Internal Layout

(Model CCD-1800-CW shown for reference)

ELECTRIC HEATERS

(OPTIONAL)

COILS

BLOWER MOTOR

FILTER ACCESS

(DOWNFLOW UNITS)

BLOWER(S)

CONDENSATE PUMP

(OPTIONAL)

AIR PROVING SWITCH & DIRTY

FILTER SWITCH (OPTIONAL)

HUMIDIFIER

(OPTIONAL)

ELECTRIC BOX

CHILLED WATER VALVE

PREFERRED POWER

SELECTOR SWITCH

(OPTIONAL)