(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

APPENDIX A - FORMS

Stulz Air Technology Systems Inc.

Frederick, Maryland USA 21704

Telephone: (301) 620-2033 Facsimile: (301) 620-1396

Checklist for Completed Installation

Frederick, Maryland USA 21704

Telephone: (301) 620-2033

Facsimile: (301) 620-1396

Air Technology Systems, Inc.

❏

1

Proper clearances for service access have

been maintained around equipment.

❏

2

Equipment is level and mounting fasteners (if

applicable) are tight.

❏

3

Piping completed to refrigerant or coolant loop

(if required).

❏

4

All field installed piping leak tested.

❏

5

Refrigerant charge added (if required).

❏

6

Condensate pump installed (if required).

❏

7

Condensate drain line connected and trap is

filled with water.

❏

8

Water supply line connected to humidifier

(if required).

❏

9

Safety pan installed under ceiling mounted

equipment (if required).

❏

10

Filter box installed (if required).

❏

11

Filter (s) installed (if required).

❏

12

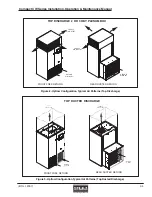

Ductwork completed or optional plenum

installed (if required).

❏

13

Incoming line voltage matches equipment

nominal nameplated rating ± tolerances.

❏

14

Main power wiring connections to the

equipment, including earth ground, have been

properly installed.

❏

15

Customer supplied main power circuit breaker

(HACR type) or fuses have proper ratings for

equipment installed.

❏

16

All wiring connections are tight.

❏

17

Control wiring connections completed to

optional equipment and devices including wiring

to a wall mounted control panel (if required).

❏

18

Foreign materials have been removed from

inside and around all equipment installed

(shipping materials, construction materials,

tools, etc.).

❏

19

Inspect all piping connections for leaks during

initial operation.

A-1