(© Oct, 2007)

Air Technology Systems, Inc.

Compact CW Series Installation, Operation & Maintenance Manual

2-9

2.8.2

Controls

SATS offers a wide range of control features to solve

your air conditioning control/alarm requirements. The

Compact CW system is furnished with a C1002 or

C6000 Microprocessor controller. If it is mounted on

the unit (standard), no utility connection is required. As

an option a factory supplied display may be remote

mounted. A six-conductor cable harness is provided for

interconnect wiring. Refer to the electrical drawing

provided with the unit for details on interconnecting

field wiring.

2.8.3

Optional Equipment

Additional control conductors may be required depend-

ing on the options purchased with the equipment.

Refer to the electrical diagram supplied with your unit

to determine the total number of interconnecting

conductors required for your system. It is important to

note that control transformer(s) supplied with the

equipment are sized and selected based upon the

expected loads for each system.

CAUTION

Do not connect any additional loads to the sys-

tem control transformers. Connecting additional

loads to the factory supplied control transformer

may result in overloading of the transformer.

NOTE

All wiring must be provided in accordance with

local and national electrical code requirements.

2.7.3.1 Remote Temperature/Humidity Sensor

The remote temperature/humidity sensor requires a

three conductor shielded cable, with the shield

terminated at the unit electric box. Both the electric

box and the sensor are provided with a terminal strip

for the wire connections. Refer to the electrical

schematic supplied with your unit for proper wire

terminations.

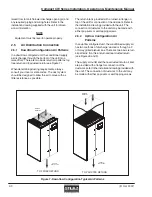

2.7.3.2 Remote Water Detector

Each remote water detector used will require two

conductors to be wired to the control terminal board

within the unit electrical box (see Figure 13). The wire

insulation must be rated at 600V. Refer to the electri-

cal schematic supplied with your unit for proper wire

terminations.

The number callouts in Figure 13 coincide with the

numbered items listed below:

1. Control I/O Board

2. Interface Terminals

3. Main Power Disconnect Switch

4. Ground Lug

5. Power Switches/Motor Start Protectors

(Quantity varies by size of A/C unit)

6. Water Detector Circuit Board (Optional)

7. Transformer Circuit Breakers

CAUTION

Improper wire connections may result in the re-

verse rotation of the fans/blower motors and may

eventually result in damage to the unit. To cor-

rect this problem, exchange any two of the in-

coming main power wires at the main power dis-

connect switch. Do NOT rewire the unit's indi-

vidual components.

CAUTION

Prior to unit operation, an adequate unit-to-earth

ground must be connected to the unit.

4

1

3

5

2

6

7

Figure 13- Electric Box