(© Oct, 2007)

Air Technology Systems, Inc.

Compact CW Series Installation, Operation & Maintenance Manual

2-7

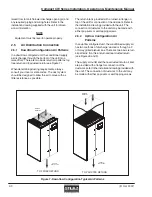

supplied with your unit for the location of the openings.

Generally, all pipe connections (sweat connections)

terminate inside the unit. Upflow (CCU) units may be

provided with (optional) pipe connections protruding

from the top of the unit.

For pipe connection sizes, refer to the following table:

Field piping is not necessarily the same size as the

unit connections. Piping should be sized to match the

required system pressure drop and flow capacity, and

may require reducing fittings to match the connection

size on the air conditioner. A filling connection and

several shrader valves are installed in the A/C unit.

Refer to the piping diagram supplied with your unit.

CAUTION

When installing and filling the chilled water and/

or hot water loops, all air must be bled from the

piping system and the piping system must be

cleaned prior to operating the system. Failure to

do so could result in equipment problems.

NOTE

All chilled water lines must be insulated to

prevent condensation from forming on the pipes.

2.7.2

Condensate Drain

2.7.2.1 Gravity Drain

A 7/8 inch OD copper (sweat type) line is provided to

drain the condensate pan. An “S” trap is installed at

the end of piping for the installer to connect a 7/8 inch

ID drain line to remove water from the cabinet. This line

also drains the optional humidifier.

NOTE

The humidifier drains (hot) water into the

condensate drain during normal operation.

The drain line must be located so it will not be ex-

posed to freezing temperatures. The diameter of the

drain line should be the full size of the connection.

NOTE

Pour some water into the condensate drain

pan(s) prior to start-up. This fills the trap and

prevents air from being drawn up the drain lines.

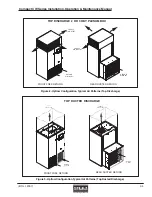

2.7.2.2

Condensate Pump

An optional condensate pump is normally factory

installed. The drain connection line may be 1/2” ID

vinyl tubing or a 1/2” O.D. copper (sweat connection)

may be used.

If an optional field installed condensate pump is used,

a p-trap must be installed to allow proper condensate

drainage (see Figure 11). The height of the trap must

be a minimum of 2 inches on standard systems to

ensure proper water drainage. The condensate pump

discharge line should be 1/2 inch O.D. (maximum)

copper pipe to prevent excessive back flow to the

condensate pump.

2.7.3

Humidifier

Compact CW systems utilize an electrode steam

humidifier. The humidifier empties into the condensate

drain line during the flush/drain cycle. A water supply

line must be connected to the ¼ inch O.D. copper

tubing connection supplied by the factory. The humidi-

fier requires normal tap water for the water supply. If

the supply water is high in particulate, an external filter

may be needed. Do not use de-mineralized water.

Refer to the humidifier operator’s manual, supplied with

the equipment, for complete manufacturer’s informa-

tion on the humidifier and the supply water recommen-

dations.

INLET/OUTLET PIPE CONNECTIONS

CW

HW

Model #

(Inches O.D.) (Inches O.D.)

CCU/D-300

1 1/8”

7/8”

CCU/D-600

1 5/8”

7/8”

CCU/D-900

1 5/8”

7/8”

CCU/D-1500

2 1/8”

7/8”

CCU/D-1800

2 1/8”

7/8”

INLET 7/8" OD

OUTLET 1/2" OD

NOTES:

1. MIMIMUM HEIGHT IN INCHES.

2. P-TRAP MUST BE LOCATED IN THE INLET SIDE OF PUMP WHEN FIELD INSTALLED.

2.00

SEE NOTE 1

SEE NOTE 2

Figure 11- Condensate Pump