(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

2-6

CAUTION

Take care not to damage the exposed tempera-

ture/humidity sensors on the PC board while screw-

ing in the cover fastening screw. The sensors can

be damaged if handled improperly.

2.6.5.1 Types of control

Room Air Control (standard)- The A/C unit is provided

with a temperature and humidity (T/H) sensor, factory

mounted in the return air stream of the A/C unit. The

return air temperature and humidity are monitored by

the system controller and compared to limit values set

at the factory. Control outputs are based on setpoints

entered into the system controller by the user.

As an alternative to locating the T/H sensor inside the

A/C unit, it may be field installed on a wall in the

conditioned space for sensing actual room conditions.

Supply Air Control- As an option, a field installed T/H

sensor may be used for supply air control. The sensor

is field installed in the supply air stream. The supply

air temperature and humidity are monitored by the

system controller and compared to limit values set at

the factory. Control outputs are based on setpoints

entered into the system controller by the user.

Room Air Control with Supply Air Limitation- The

controller monitors the T/H sensor located in the

return air stream and the T/H sensor located in the

supply air stream. Control is similar to “Room Air

Control” except, the temperature setpoint is automati-

cally increased by the controller when the measured

supply air temperature exceeds the Start Temperature

entered by the user. The extent of the setpoint

increase is determined by a factor which the user

enters in the controller as a gradient. A high gradient

significantly corrects the failure to meet the supply air

tempertaure but has the risk that the control circuit

starts to hunt.

With humidity control, the setpoint shift acts in the

opposite direction. If the starting humidity entered by

the user is exceeded by the measured supply air

humidity, the setpoint is autimatically reduced by the

controller. The user may also enter a gradient factor

for humidity control.

Formula:

New setpoint = old s [gradient • (start value -actual

value)]

Example (temperature): 70.5 = 70 + [0.5 • (61 - 60)]

Example (humidity): 49 = 50 + [0.5 • (70 - 72)]

Supply Air Control with Room Air Limitation- Based

on the same principle as “Room Air Control with

Supply Air Limitation” however, in this case the

setpoint shift works in the opposite direction on the

basis that the supply air is colder than the return air.

The temperature setpoint is automatically reduced by

the system controller when the measured room air

temperature exceeds the Start Temperature entered

by the user. The humidity setpoint is automatically

increased by the system controller when the mea-

sured room humidity drops below the starting humidity

entered by the user.

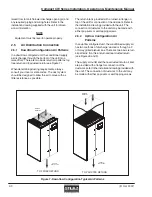

2.6.6

Remote Water Detector

The remote water detector is normally placed on the

sub-floor or in a field supplied auxiliary drain pan located

beneath the unit. SATS provides 2 types of water

detectors:

Spot type water detector-

Remove the protective cover and connect two control

wires to the terminals on the base

(terminal lugs are provided). Place the

water detector(s) on the floor with the

metal electrodes facing down. The base

is provided with a mounting hole in the

center which may be used to secure the water detec-

tor in place. Replace the cover. When water is present,

current will flow between the electrodes.

NOTE

Do not place the spot type water detector on

an electrically conductive surface.

Cable type water detector-

Lay the cable water detector flat across the sub-floor

where water could collect.

When water is present,

current will flow between the

two wires. A two conductor

wire harness is provided with a

quick connect fitting on the end. The harness mates to

the fitting on the water detector and connects it to the

control board inside the electric box.

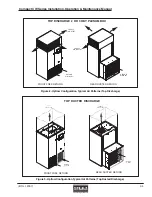

2.7

Piping Connections

2.7.1

Chilled Water/Hot Water

For CCD (downflow) units, the pipe openings for the

chilled water and optional hot water reheat piping are

located in the base of the unit. For CCU (upflow) units,

pilot holes are provided inside the unit in the lower side

panel(s). These pilot holes may be enlarged from

inside the unit. Refer to the installation drawing