(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

1-5

1.5.6

Temperature/Humidity Sensor

As a standard for room air control, a temperature/

humidity (T/H) sensor is factory mounted in the return

air stream. The (T/H) sensor monitors the return air

conditions and provides input signal(s) to the system

controller to manage the operation of the A/C unit

consistent with the setpoints entered in the system

controller.

1.5.7

Humidifier (Optional)

Compact CW systems utilize an electrode, steam

humidifier. The humidifier is factory installed inside the

air conditioner and includes fill and drain valves and

associated piping. Operation of the humidifier’s fill and

drain cycles is based on water conductivity and is

maintained by the humidifier controller. An operating

manual for the humidifier is provided under separate

cover. Refer to that manual for detailed information on

operation of the humidifier.

1.6 Optional Equipment

1.6.1

Condensate Pump

An optional condensate pump may be used for auto-

matic removal of condensate from the air conditioner

and flush water from the humidifier. An internal overflow

safety switch is wired to the system controller to

automatically shut down the precision A/C system

should an overflow occur.

1.6.2

Smoke Detector

Optionally mounted in the return air stream, a photo-

electric smoke detector is used to sense the presence

of smoke and signal the controller when a smoke

alarm condition exists.

1.6.3

Firestat

Optionally mounted in the return air stream, a fire

detector senses high retun air temperature and signals

the controller when a fire alarm condition exists.

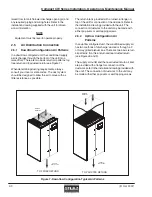

1.6.4

Auto Transfer Switching

An automatic transfer, main power switching system is

optionally available for critical operation. With this

option, two main power service disconnect switches are

provided on the door of the cabinet to connect two

independent power sources, (see Figure 2). If the user

selectable, main power source is interrupted, or if a

phase loss or imbalance occurs, the automatic transfer

switching circuitry immediately transfers operation of

the precision A/C system to the secondary power

source. If power is transferred, the system controller

provides an alarm signal and the alarm display indicates

which power source failed. When the primary power

source is functionally restored, the A/C system load is

automatically transferred back to the primary power

source.

With the auto-transfer switching option, a preferred

power selection switch is mounted inside the cabinet

to the top of the electric box, (see Figures 1 & 3). This

switch may be used to manually transfer the power

source and/or to test the auto transfer switching

function.

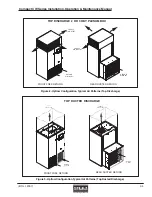

1.6.4.1

Indicator Lights

As an additional option, an indicator light may be

provided above each main power service disconnect

switch for a visual indication that power is available.

Figure 3- Preferred Power Selection Switch

Figure 2- Auto Transfer Disconnect Switches

OPTIONAL DUAL

DISCONNECT SWITCHES

(LOCATION MAY VARY)

INDICATOR LIGHTS

(OPTIONAL)

FRONT DOOR OF

A/C SYSTEM