(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

1-1

1.0

INTRODUCTION

1.1

General

Congratulations, the

Compact CW™ floor mounted

precision air conditioning system covered by this

manual is designed and manufactured by Stulz Air

Technology Systems, Inc. (SATS) using the latest,

state-of-the-art control technology. Recognized as a

world leader, SATS provides air conditioning systems

with the highest quality craftsmanship using the finest

materials available in the industry. The unit will provide

years of trouble free service if installed and maintained

in accordance with this manual. Damage to the unit

from improper installation, operation or maintenance is

not covered by the warranty.

STUDY the instructions contained in this manual.

They must be followed to avoid difficulties. Spare parts

are available from SATS to insure continuous opera-

tion. Using substitute parts or bypassing electrical or

cooling components in order to continue operation is

not recommended and will VOID THE WARRANTY.

Due to technological advancements, components are

subject to change without notice.

All

Compact CW systems are designed to be installed

indoors, unless otherwise noted on the equipment.

1.2

Product Description

Compact CW systems are designed to be the most

versatile and flexible floor mounted precision air

conditioning systems in the industry. The unit is

available in up-flow or down-flow configurations. The

cooling capacity, in kW, will depend on the unit size,

which can range from 30 to 180 kW, (1 kW = 3415

BTU/Hr). Refer to the unit nameplate to identify the

model number and cooling capacity of your unit.

Compact CW systems operate with an external

source of chilled water. The chilled water system is a

closed loop circuit in which cold water is circulated

through a chilled water coil. On demand for cooling,

the microprocessor controller begins modulating the

chilled water valve open. Chilled water flows to the coil

at a rate that varies proportionally to the amount of

cooling required to meet the user selectable tempera-

ture setpoint. Heat from the surrounding air is trans-

ferred through the finned tubing of the coil into the cold

water. Water is then re-circulated back to the cold

water source.

Compact CW systems have been designed to supply

air to only one room.

NOTE

Compact CW systems are strictly for non-resi-

dential applications.

The functional modes of operation, in addition to

cooling, are heating, humidification and dehumidifica-

tion, which provide complete environmental control of a

conditioned space.

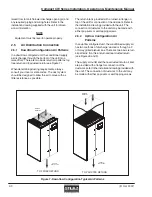

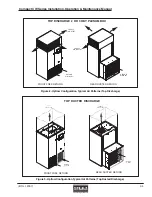

There are two air pattern configurations, upflow and

downflow, and several cabinet sizes based on the type

of system and capacity. Regardless of configuration,

the

Compact CW system is compact and versatile.

See the Installation drawing provided with the unit for

the layout and dimensions of the cabinet.

The

Compact CW unit is provided with a factory

mounted, main power disconnect switch with a lockable

handle. The disconnect switch electrically isolates the

unit during routine maintenance. The system incorpo-

rates state of the art component protection with the use

of motor start protectors and circuit breakers.

An operating manual for the system controller is

provided under separate cover. Refer to that manual for

detailed instructions on operating the system control-

ler provided with your unit.

The standard controller for

Compact CW precision A/C

units sizes CCD/U-300 through CCD/U-900 is SATS

model C1002. For larger units, CCD/U-1500 through

CCD/U-1800, the standard controller is the SATS

model C6000. These microprocessor controllers

provide the following features: input/output monitoring

status, full integrated control of heating, cooling,

humidification and dehumidification; multi-unit control

and remote communication with building management

systems. The controller is typically factory mounted

on the front hinged access door of the unit. As an

option the controller may be remotely mounted to a

wall or control panel.

SATS offers the C6000 microprocessor controller as

an option for models CCD/U-300 through CCD/U-900

A/C units.

C1002

C6000