(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

2-10

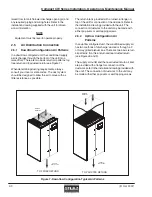

Figure 14- Blower Assembly

MOTOR

BASE

MOTOR

TENSION ROD

ADJUSTMENT

BLOWER

LOCK DOWN

PLATE

ADJUSTABLE

SHEAVE

JAM NUT

BASE LOCKING

BOLT

2.9

System Settings and Adjustments

2.9.1

Chilled Water Circuit

In a chilled water A/C unit, cooling is maintained by

flowing chilled water through a cooling coil. A water

valve proportionally opens to increase fluid flow as the

temperature rises (or closes as the temperature falls).

If the unit is turned off, the valve will return to the

closed position, shutting off flow through the coil.

Chilled Water control valves are available in 2-way or 3-

way configurations. Refer to the piping drawing

supplied with your unit to determine which type valve is

provided.

Location and size of chilled water valves differs with

the size of the A/C unit. The chilled water valves are

factory set for the correct operation and should not

require field adjustment.

2.9.2 Humidifier Adjustment

The humidifier has a capacity adjustment potentiom-

eter on the humidifier control circuit board. The capac-

ity potentiometer may need to be field adjusted if the

humidifier is not supplying enough capacity for current

room conditions.

It is recommended that if the humidifier capacity

potentiometer requires adjustment, the adjustment is

made in small increments and verified. Refer to the

humidifier manual sent with your unit for the capacity

potentiometer location.

CAUTION

Adjusting the capacity potentiometer too high may

result in formation of condensation within the system.

2.9.3

Blower

The blower motor (see Figure 14) is supplied with an

adjustable sheave (pulley), to change blower speed, and

an adjustable base for belt tensioning. Use the following

procedure to change the blower speed.

1.

Turn the A/C system off.

2.

Turn off all power to unit at the main power discon-

nect switch; use lock-out tag-out procedure.

3.

Remove the blower belt(s).

4.

Loosen the set screw in the side of the motor

sheave with an allen wrench.

5.

Remove the sheave key.

6.

Adjust blower speed by closing the sheave one half

turn to increase speed or opening the sheave one

half turn to decrease speed.

7.

Replace the sheave key and tighten set screw.

8.

Proper belt tension is achieved when the belt has a

deflection of ¾ inch per foot of span between the

blower and motor pulleys, with firm pressure

placed mid-span on the blower belt. To adjust

blower belt tension, loosen the locking bolt on the

side of the motor base. Turn the jam nut away from

the lockdown plate. Rotate the tension rod to move

the motor on it’s base to increase or decrease belt

tension. Re-tighten the jam nut and tighten the

locking bolt on the motor base.

CAUTION

If the belt tension is too tight, it will cause premature

blower and/or motor bearing failure. If the belt is too

loose, the belt will slip and cause belt squeals and

eventual belt failure.

9.

Restore power to system.

10. Check the current draw on the blower motor to

make sure it does not exceed the nameplate

rating of the motor.

11. If current draw exceeds nameplate rating of motor,

repeat steps 1 through 9 to decrease the blower

speed. If the motor pulls too much current, slow

the blower down by opening the adjustable sheave

one half turn at a time, until the motor current is at

or below the nameplate FLA.

12. Check the motor overload on the blower starter to

confirm its setting is correct for the FLA of the motor.