(© Oct, 2007)

Air Technology Systems, Inc.

Compact CW Series Installation, Operation & Maintenance Manual

2-3

raised floor to match blower discharge opening(s) and

any required piping and wiring holes. Refer to the

installation drawing supplied with the unit for dimen-

sional information.

NOTE

Equipment must be level to operate properly.

2.5

Air Distribution Connection

2.5.1

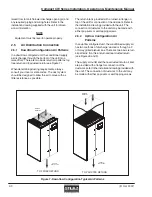

Downflow Configuration Air Patterns

In a downflow configured unit, the conditioned supply

air discharges through the bottom of the unit into a

raised floor. There are two basic return air patterns: top

free return and top ducted return (see Figure 7).

When determining ducting requirements, always

consult your local or state codes. The duct system

should be designed to allow the air to move with as

little resistance as possible.

The return inlet is provided with a turned-in flange on

top of the unit for connection of the ductwork. Refer to

the installation drawing provided with the unit. The

connection of ductwork to the unit may be made with

either pop rivets or self-tapping screws.

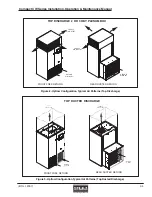

2.5.2

Upflow Configuration Air

Patterns

In an upflow configured unit, the conditioned supply air

has two methods of discharge: ducted or through a 2

or 3-way grilled plenum box. There are two basic return

air patterns: front free return and rear ducted return

(see Figures 8 and 9).

The supply air outlet and the rear ducted return air inlet

are provided with a flange for connection of the

ductwork (refer to the installation drawing provided with

the unit). The connection of ductwork to the unit may

be made with either pop rivets or self-tapping screws.

TOP FREE RETURN

TOP DUCTED RETURN

RETURN

AIR INLET

SUPPLY

AIR OUTLET

RETURN

AIR INLET

SUPPLY

AIR OUTLET

Figure 7- Downflow Configuration Typical Air Patterns