(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

1-3

1.4

Safety

1.4.1

General

Stulz Air Technology Systems, Inc. uses

NOTES

along with

CAUTION

and

WARNING

symbols through-

out this manual to draw your attention to important

operational and safety information.

A bold text

NOTE

marks a short message in the

information to alert you to an important detail.

A bold text

CAUTION

safety alert appears with

information that is important for protecting your

equipment and performance. Be especially careful to

read and follow all cautions that apply to your applica-

tion.

A bold text

WARNING

safety alert appears with

information that is important for protecting you from

harm and the equipment from damage. Pay very

close attention to all warnings that apply to your

application.

A safety alert symbol

accompanies a general

WARNING

or

CAUTION

safety statement.

A safety alert symbol

accompanies an electrical

shock hazard

WARNING

or

CAUTION

safety state-

ment.

1.4.2

Safety Summary

The following statements are general guidelines

followed by warnings and cautions applicable

throughout the manual.

Prior to performing any installation, operation, mainte-

nance or troubleshooting procedure, read and under-

stand all instructions, recommendations and guide-

lines contained within this manual.

All maintenance and/or repairs must be performed by

a journeyman, refrigeration mechanic or an air

conditioning technician.

Never operate the unit with any cover, guard, screen,

panel, etc., removed unless the instructions specifi-

cally state otherwise, then do so with extreme caution

to avoid personal injury.

Never lift any component in excess of 35 pounds

without help. If a lifting device is used to move a unit,

ensure it is capable of supporting the unit.

When working on electrical equipment, remove all

jewelry, watches, rings, etc.

Always disconnect the main power supply to the

equipment at the main power disconnect switch before

beginning work on the equipment. A lock-out tag-out

procedure should be followed to ensure that power is

not inadvertently reconnected.

Equipment may contain components subject to

Electrostatic Discharge (ESD). Before attempting to

mount or service these electronic devices, ensure

you have no charge built up by touching a ground

source. When possible, use a wrist-grounding strap

when working on or near electronic devices.

Never work on electrical equipment unless another

person who is familiar with the operation and hazards

of the equipment and competent in administering first

aid is nearby.

All personnel working on or near equipment should be

familiar with hazards associated with electrical

maintenance. Safety placards/stickers have been

placed on the unit to call attention to all personal and

equipment damage hazard areas.

Certain maintenance or cleaning procedures may call

for the use and handling of chemicals, solvents, or

cleansers. Always refer to the manufacturer's Material

Safety Data Sheet (MSDS) prior to using these

materials. Clean parts in a well-ventilated area. Avoid

inhalation of solvent fumes and prolonged exposure

of skin to cleaning solvents. Wash exposed skin

thoroughly after contact with solvents.

CAUTION

When the air conditioner is in the cooling mode,

the return air-intake and discharge (supply)

must be free of obstructions. Ensure panels are

secure and latched into position.

CAUTION

Do not use cleaning solvents near open flame or

excessive heat. Wear eye protection when blow-

ing solvent from parts. The pressure-wash should

not exceed 30 psig. Solvent solutions should be

disposed of in accordance with local and state

regulatory statutes.

CAUTION

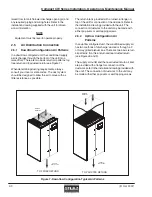

The unit must be kept level and vertical in its

normal installed position.