E_MH_Installation_instructions_Skylux_Climax

20/11/2020

56/88

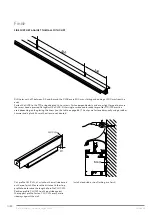

Glazing: plastic sheets

Preparation

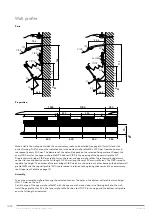

gutter

Glazing

GD1+G

GD2+G

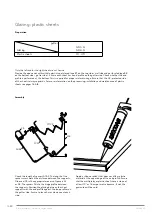

Plastic sheets

10 - 45°

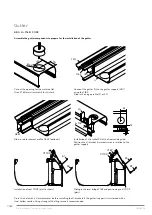

Only the left and/or the right sheet are cut to size.

Provide the open ends with suitable plastic tape (closed tape BT on the top side = wall side and perforated tape BB

on the bottom side = gutter side). Ensure each sheet has a end profile on the gutter side. Check whether the end

profile is perforated at the bottom. This is required for proper water drainage. Ensure that the UV-protected side

of the sheet is always upwards. For more information on the processing, installation and maintenance of plastic

sheets see pages 16 & 18.

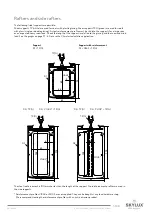

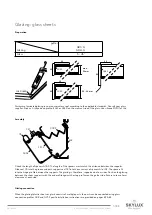

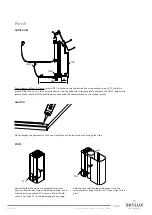

Assembly

Check the length of spacers A1/A2. The length of the

spacers must match the distance between the supports.

Slide seal C5 in the appropriate recess of spacers A1

or A2. The spacers fit into the hinge profile between

the supports. Position the glazing between the sheet

supports with the end profile against the stop profiles on

the gutter side. Ensure to leave 5 mm clearance at each

side.

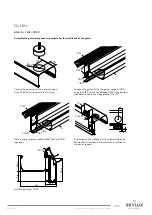

Apply a silicone sealant that does not affect plastic

material at the upper edge of the end profile. Ensure

that the multiple layer plastic sheets have a slope of

at least 10° or 18 cm per metre because, if not, the

guarantee will be void.

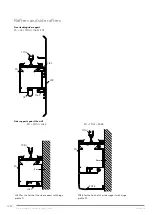

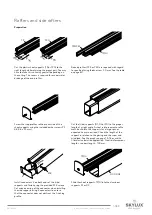

C5

A1/A2

S1/S2

C11CX

MB