SYSTEM DESCRIPTION

3

15

8022161-1B29 / V2-0/2021-04|SICK

Subject to change without notice

T R A N S L A T I O N O F A N O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | Backup Assistance System

3.2.2

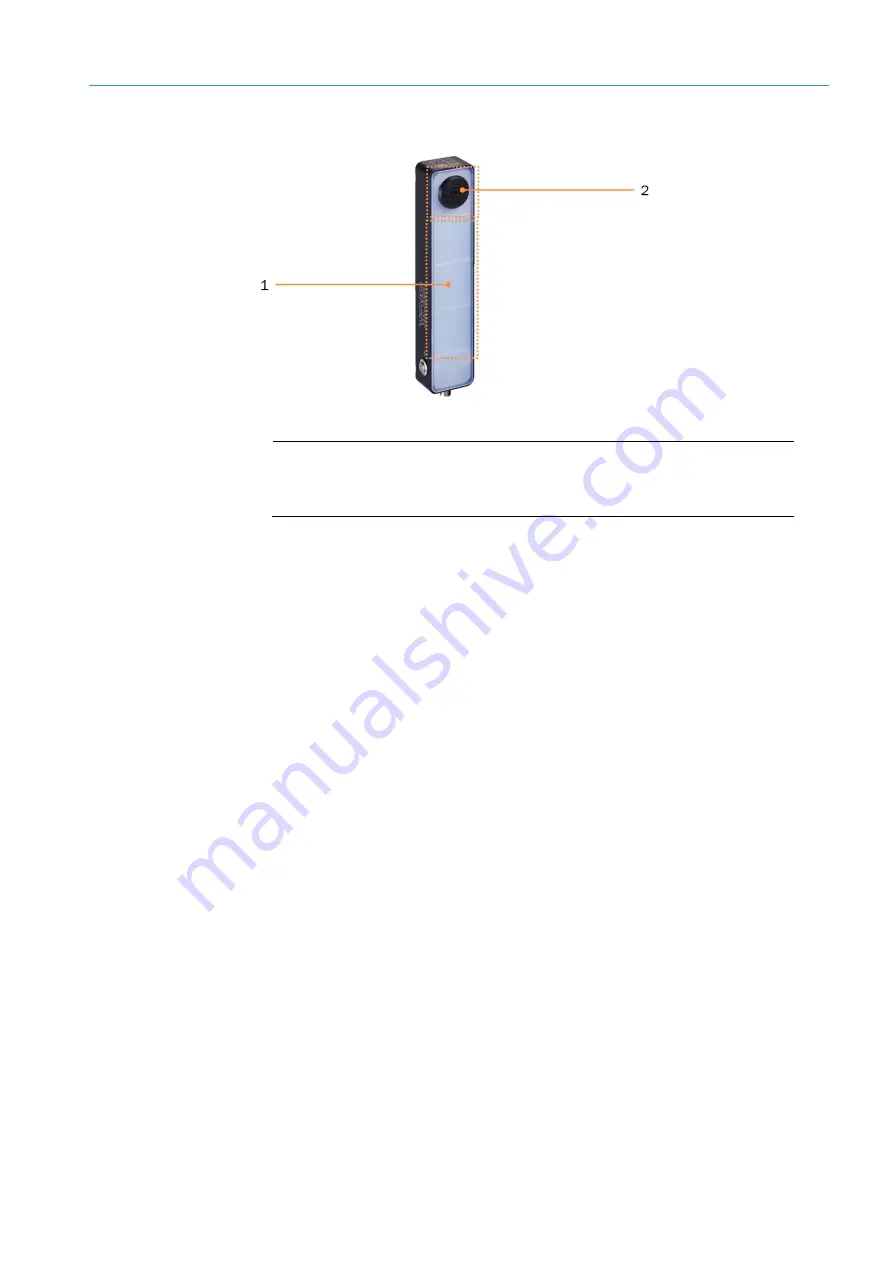

Signal light bar with buzzer

Fig. 4:

Signal light bar with buzzer

Legend

1

Light fields

2

Beeper

•

Signal light bar with bright light fields and integrated buzzer.

•

Each 2D LiDAR sensor is connected to its own signal light bar via the control unit.

•

Optical and acoustic signaling in the event of object detection within the monitoring

fields.

•

If an object is detected within

warning field 1

(=

warning

), the yellow LED lights up and

a warning tone is audible.

•

If an object is detected within

warning field 2

(=

stopping field

), the red LED lights up

and a continuous tone is audible.

Features

Function