Synergy Series Installation Guide (v18)

Basic Communications Setup • 7–11

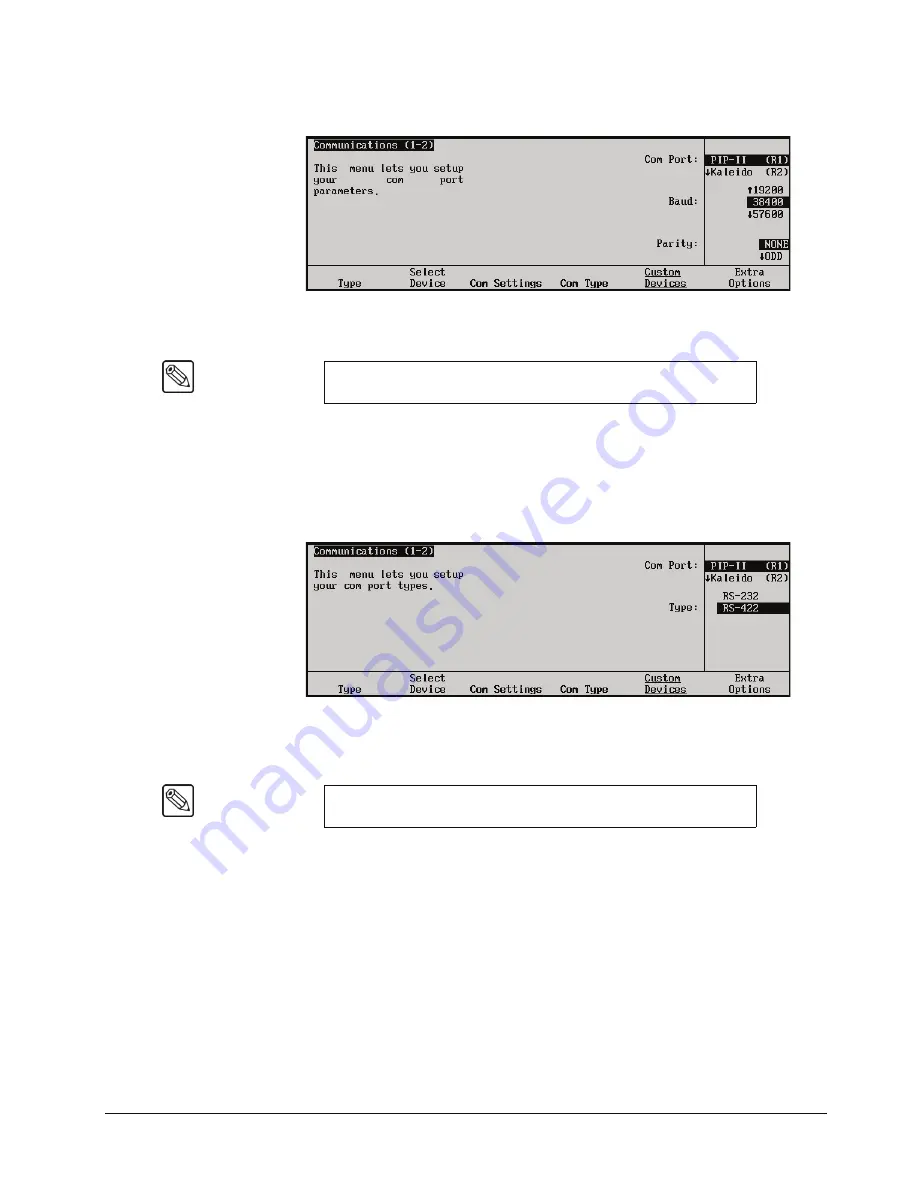

6. Press

Com Settings

to display the

Com Settings Menu

.

Communications — Com Settings Menu

7. Set the communications protocols for the PIP-II device as follows:

•

Use the

Com Port

knob

to select the PIP-II port you are setting the

communications settings for.

•

Use the

Baud

knob to select the baud rate for the PIP-II device.

•

Use the

Parity

knob to select the parity for the PIP-II device.

8. Press

Com Type

to display the

Com Type Menu

.

Communications — Com Type Menu

9. Select the type of serial communications that will be used to communicate with the

PIP-II device as follows:

•

Use the

Com Port

knob

to select the PIP-II device you want to set the

communications type for.

•

Use the

Type

knob to select the type of serial communications for the selected port.

10. Press

Extra Options

to display the

Extra Options Menu

.

Note

Refer to your PIP-II device documentation for the specific Baud and

Parity settings of your PIP-II device.

Note

Refer to your PIP-II device documentation for the specific

communications type of your PIP-II device.

Summary of Contents for Synergy 2 SD

Page 1: ...Ross Video Limited Installation Guide Volume I Software Issue 18...

Page 10: ......

Page 18: ...viii Contents Synergy Series Installation Guide v18...

Page 88: ...2 44 Installation Synergy Series Installation Guide v18...

Page 122: ...4 18 Preliminary Video Installation Synergy Series Installation Guide v18...

Page 132: ...5 10 Using the Menu System Synergy Series Installation Guide v18...

Page 156: ...6 24 BNC Configuration and Check Synergy Series Installation Guide v18...

Page 292: ...9 62 Additional Installation Setups Synergy Series Installation Guide v18...

Page 326: ...11 10 Still Stores Synergy Series Installation Guide v18...

Page 346: ...12 20 Editors OverDrive Synergy Series Installation Guide v18...

Page 394: ...GL 4 Glossary of Terms Synergy Series Installation Guide v18...