Extended capability

F-7

F.1.5

Parameter table selection

A number of ‘parameter tables’ may be available for use during operation. The purpose of

these is to allow the easy selection of a number of common options/operations.

The parameters which may be selected are shown below:

Dead path for laser encoders or reference offset from scale expansion origin

Workpiece temperature sensor serial number

Workpiece expansion coefficient

Workpiece origin offset

Workpiece origin type

The use of these switchable parameters allows such options as:

Multiple machine home positions.

Changing to an alternative machining zone.

Use of multiple workpiece material sensors (for multiple machine zones or other

reasons).

Changing of the material type (e.g. aluminium/steel)

The values for these parameters may be pre-configured at

System Configurator

level as

detailed in sections 4.2.4 and F.1.7.1, and then selected during operation by the machine

control or a simple switch.

The number of parameter tables available depends on how the system configurator has

programmed the RCU10s. A maximum of four parameter sets may be selected by use of

two hardware lines. The selection control is shown in the table below:

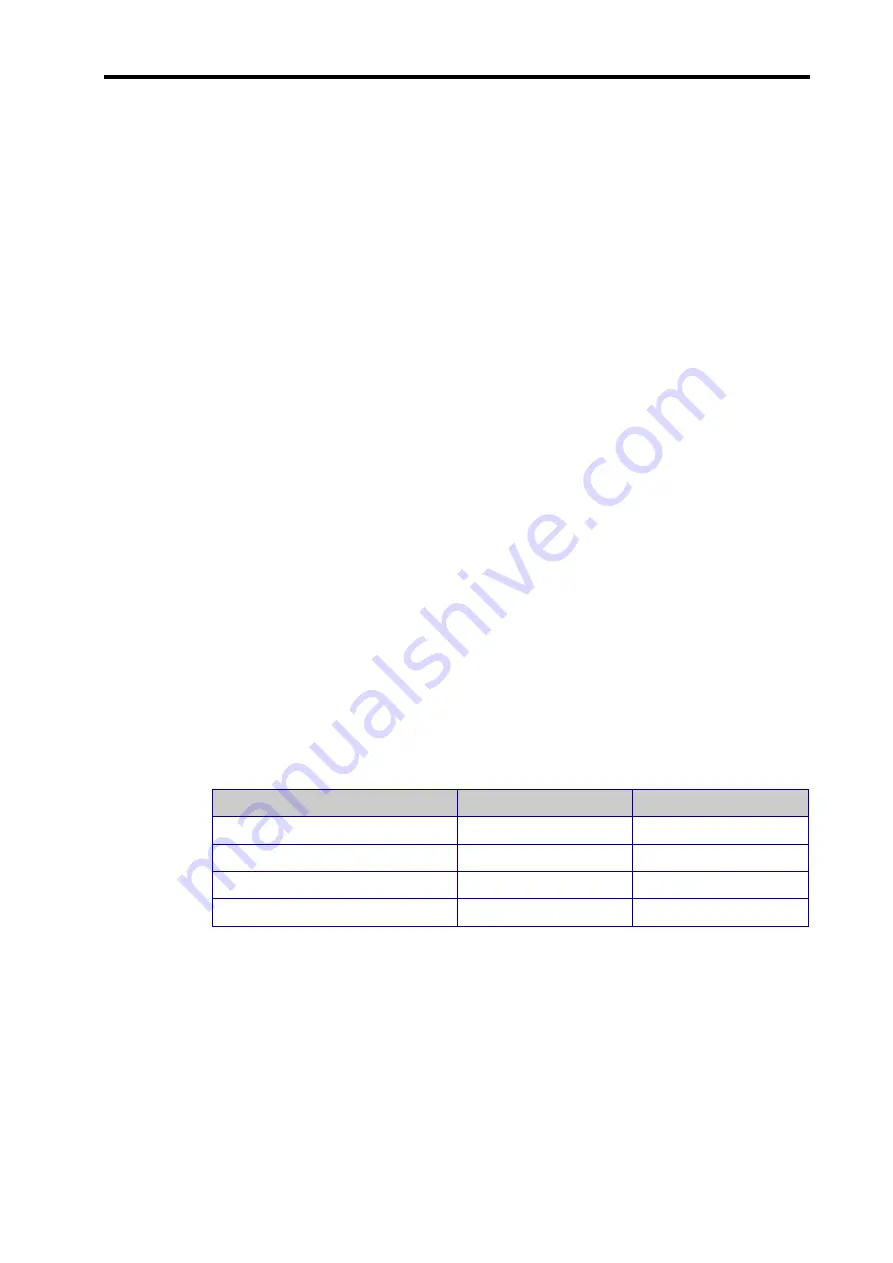

Table F.2 – Parameter table selection

Select parameter table

PT select 1

PT select 2

1

HIGH

HIGH

2

LOW

HIGH

3

HIGH

LOW

4

LOW

LOW

(NOTE:

If single parameter table operation is selected, there is not a requirement to

connect to the parameter table select lines.)

The procedure for use should be as follows:

1. Stop the machine/part program.

2. Change the selected parameter table (by use of the control lines).

3. Re-home the machine or axis. Once this is complete, the new parameter set will be

used and displayed in the software. This can be confirmed by looking at the RCU CS

status display screen to see which parameter table is shown as active.

Summary of Contents for RCU10

Page 1: ...Installation and user s guide M 9904 1122 09 A RCU10 quadrature compensation unit...

Page 11: ...viii Contents This page is intentionally left blank...

Page 23: ...1 12 System overview This page is intentionally left blank...

Page 39: ...2 16 System design...

Page 49: ...3 6 Kit configuration and part identification This page is intentionally left blank...

Page 67: ...4 18 System installation This page is intentionally left blank...

Page 91: ...A 6 RCU10 system specifications This page is intentionally left blank...

Page 147: ...E 8 Commissioning tests This page is intentionally left blank...

Page 175: ...F 28 Extended capability This page is intentionally left blank...

Page 189: ...G 14 Reference This page is intentionally left blank...

Page 193: ...H 4 Test records This page is intentionally left blank Cut here Cut here...

Page 195: ...H 6 Test records This page is intentionally left blank Cut here Cut here...