84

LD Platform Peripherals Guide

13732-000 Rev J

5.7 Specifications

VCC

GND

DIN_1-

DIN_2-

R

R

5

7

V5

R

0.10A

6

8

&

A

B

C

D

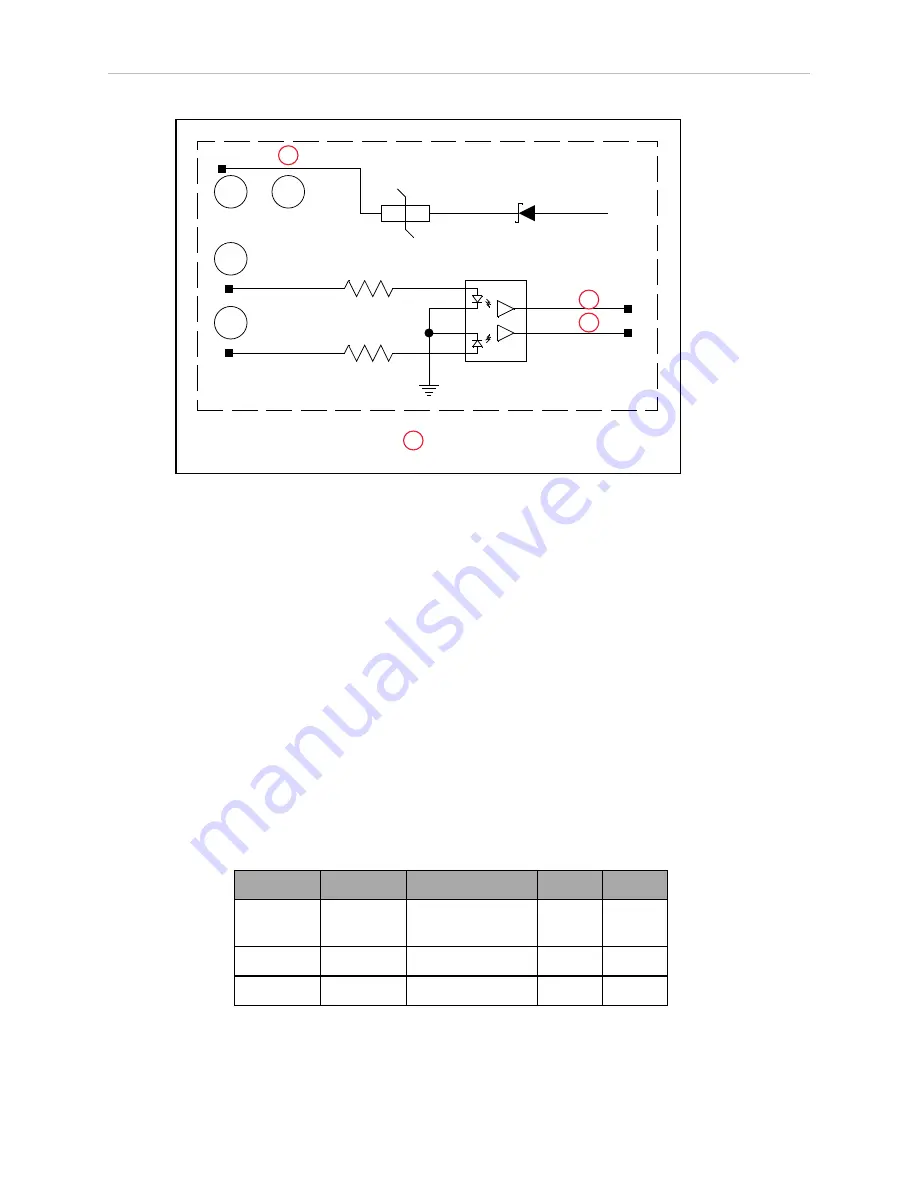

Figure 5-30

Input Circuit Schematic

Key

Meaning

Key Meaning

A Digital Input Circuit C DOOR_IN1

B SAFE_5V

D DOOR_IN2

Outputs

l

NO relay with voltage-free contacts

l

Contact rating 30 VDC, 2 A max (resistive)

l

Supports 2 inputs and 2 outputs

These have preset behavior for call buttons, which cannot be changed. The outputs can

be used for a beeper, light, or other use. Both inputs act as external push-button presses.

NOTE:

A call button can be turned into a door box with the DIP switch,

in which case the I/O can be configured by the user.

When used as a door box, Output1 is dedicated as a signal to the door actuator to open

the door. Only Output2 is available to the user.

Output1

Output2

Input1 Input2

Call Button ON when

In Progress

ON for ≥ 1 second

after Arrival

Button

press

Button

Press

Door Box

Door

user

user

user

I/O Box

user

user

user

user

l

Inputs and outputs are configured in the MobilePlanner software.

See Configuring External I/O on page 76 and Configuring an Output Signal on page 74.