Appendix 1. EMC Installation Guidelines

1.3 EMC Measures

157

1.3 EMC Measures

The main items relating to EMC measures include the following.

(1) Store the device in a sealed metal panel.

(2) Ground all conductors that are floating electrically. Decrease the impedance.

(3) Increase the distance between the drive line and signal wire.

(4) Shield the cables wired outside of the panel.

(5) Install a noise filter.

Take care to the following items to suppress the noise radiated outside of the panel.

(1) Accurately ground the devices.

(2) Use shielded cables.

(3) Increase the electrical seal of the panel. Reduce the gaps and holes.

1.4 Panel Structure

The design of the panel is a very important factor for the EMC measures, so take the following measures into

consideration.

1.4.1 Measures for Control Panel Body

(1) Use metal for all members configuring the panel.

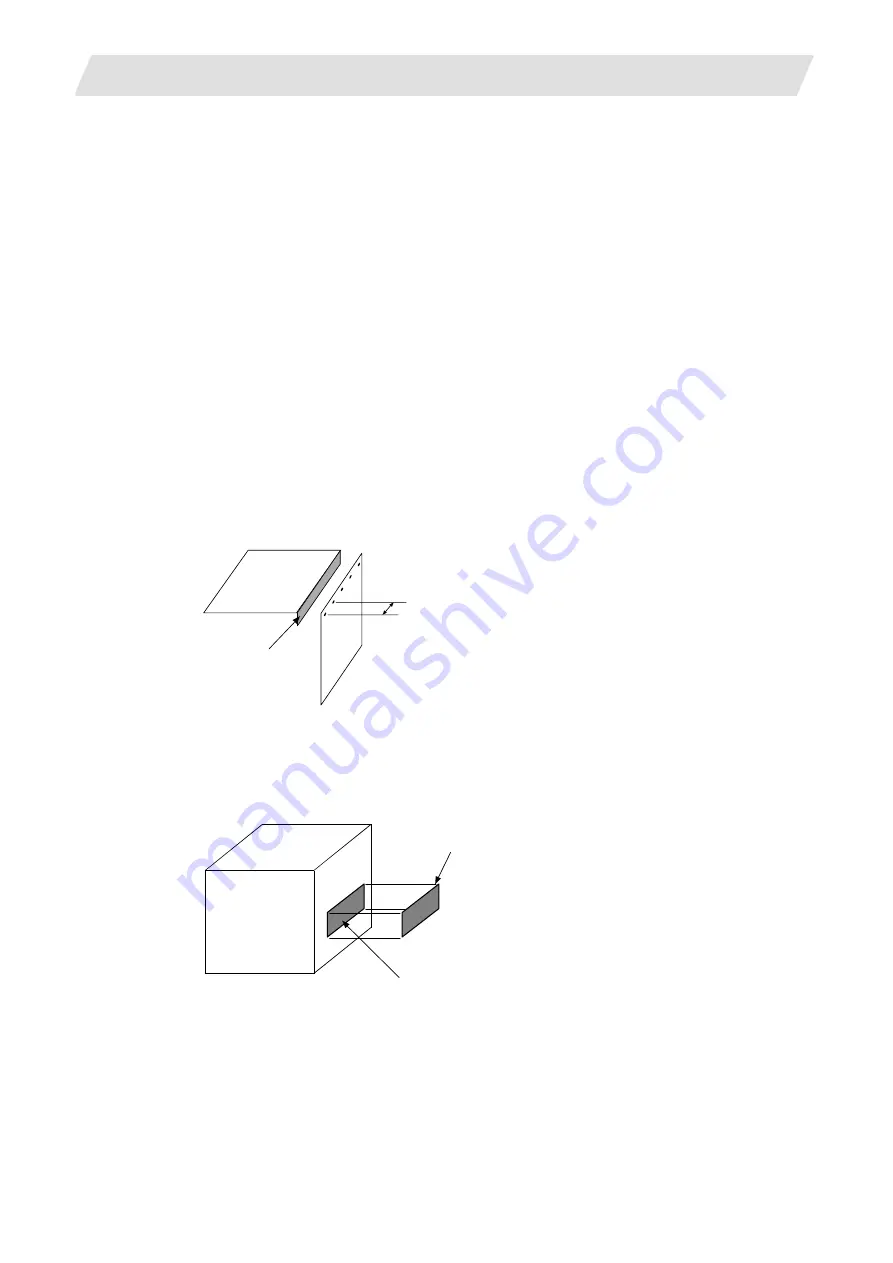

(2) When joining the metal plate, treat the welded or contacting sections so that the impedance is reduced,

and then fix with screws.

Painting mask

Joining clearance: Approx. 20cm

(3) Note that if the plate warps due to the screw fixing, etc. By creating a clearance, noise could leak from

that place.

(4) Plate (nickel tin) the metal plate surface at the grounding plate, and connect the connections with a low

impedance.

(5) If there is a large opening, such as ventilation holes, make sure to close the hole.

Mesh cover

(conductive sponge)

Opening

Control panel

(Note 1)

Using screws to fix the plates that have been painted is the same as an insulated state. Peel the

paint and fix the screws.