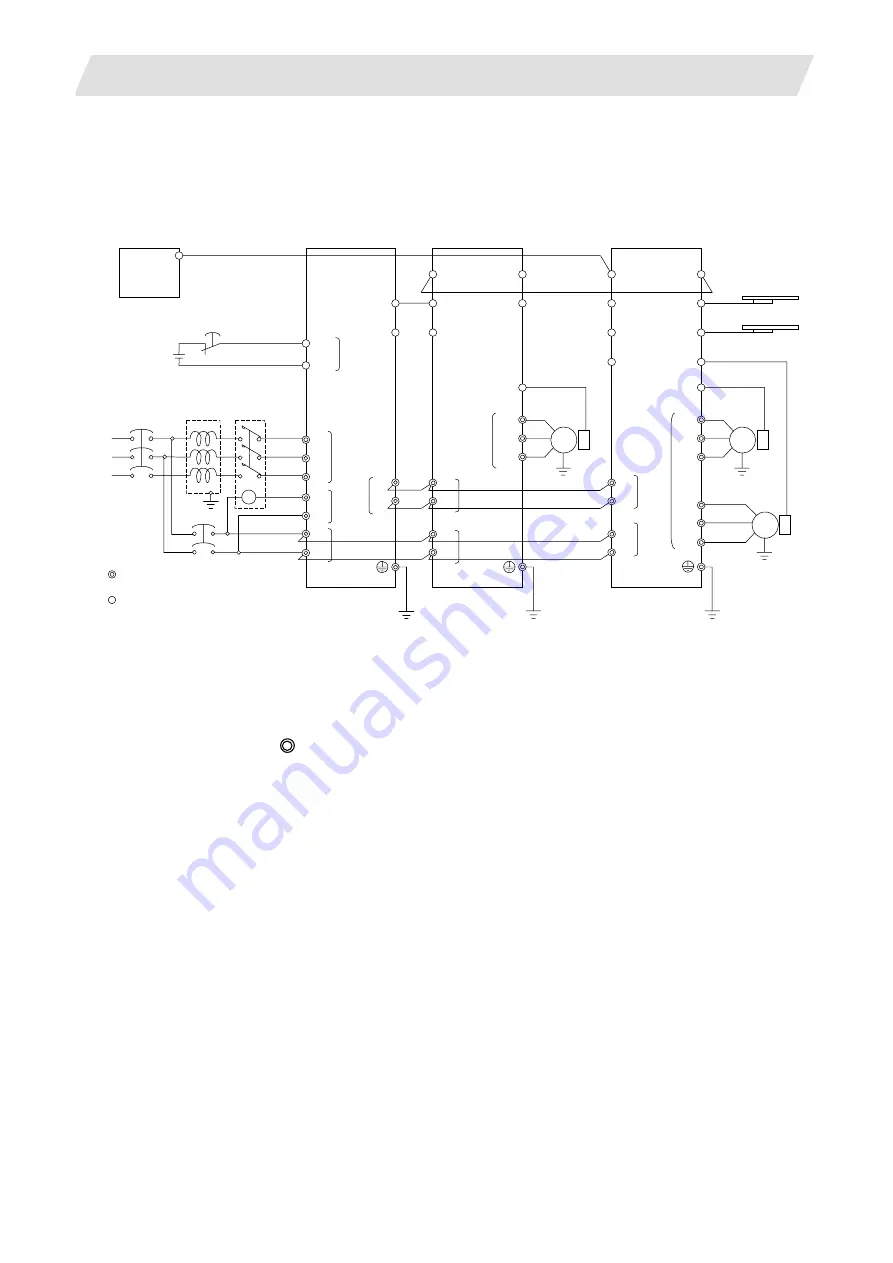

10. Basic Wiring for Servo Drive Unit

10.1 Basic Wiring for MDS-D/DH Series

152

10. Basic Wiring for Servo Drive Unit

10.1 Basic Wiring for MDS-D/DH Series

The basic wiring for the MDS-D/DH Series is shown below.

MC2

Mitsubishi CNC

OPT1,2

External emergency

stop input

T

S

R

Contactor

No-fuse

breaker

Ground

: Main circuit

: Control circuit

CN1A

CN23A

CN4

CN9

L1

L2

L3

L11

TE3

TE1

CN9

CN1B

L+

L-

U

V

W

CN2

TE1

PLG

Spindle drive unit

Power supply unit

Spindle

motor

CN4

TE3

TE2

L+

L-

L11

L21

TE2

AC

reactor

Ground

Ground

L21

CN3

CN1A

CN4

CN9

CN20

CN1B

MU

MV

MW

CN2L

CN2M

LU

LV

LW

TE1

Motor side

detector

Motor side

detector

Servo drive unit

Servo

motor

Servo

motor

Machine side

detector

Machine side

detector

TE3

TE2

L+

L-

L11

L21

Ground

CN3L

CN3M

Breaker

Optical communication cable

Optical communication cable

MC1

CN23B

SH21

cable

EMG1

EMG2

24VDC

MC

(Note 1)

The total length of the optical communication cable from the NC must be within 30m and the

minimum-bending radius within 80mm.

(Note 2)

The connection method will differ according to the used motor.

(Note 3)

Battery for the detector back up is built-in the drive unit. (An external battery is available as an

option.)

(Note 4)

The main circuit (

) and control circuit (

{

) are safely separated.