Lower Feeder Units (Trays 3 and 4)

158

17

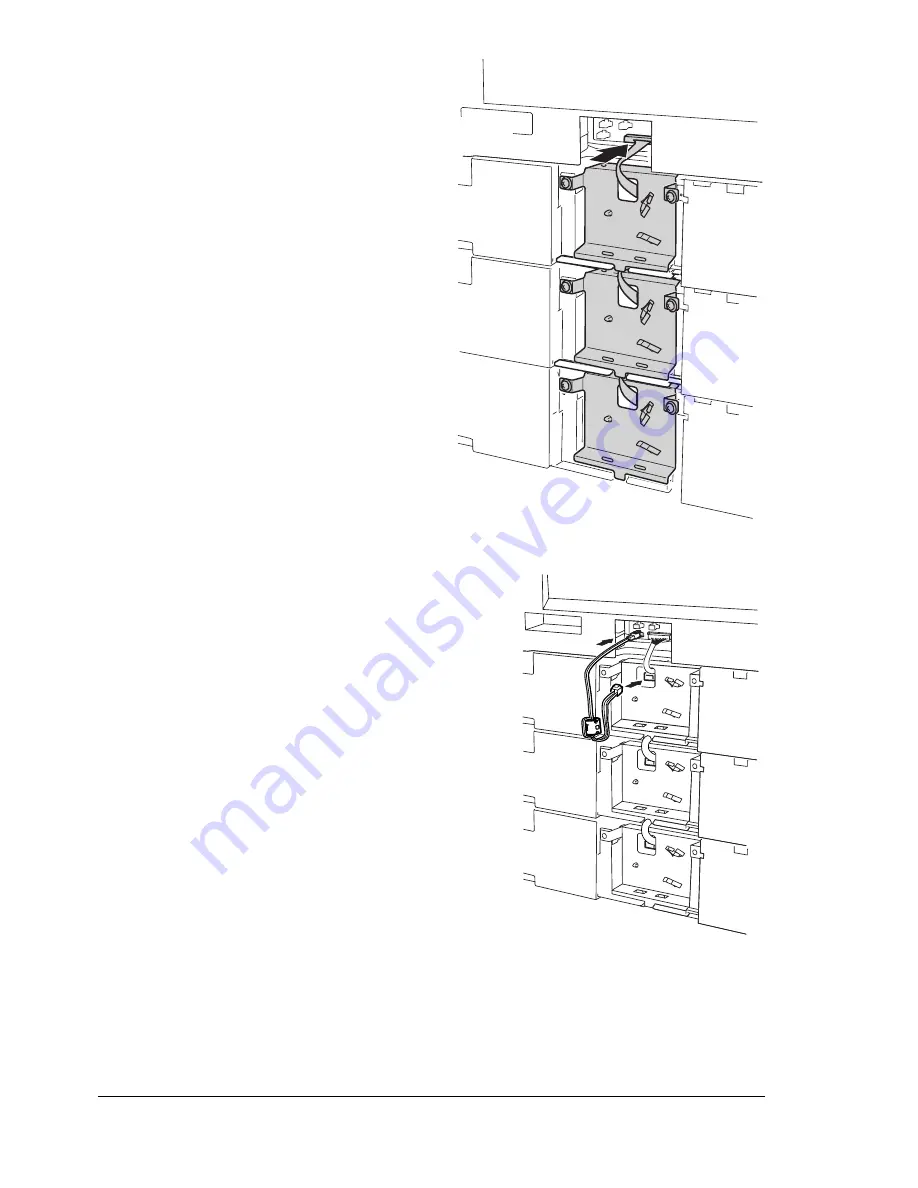

Connect the other end of the

control harness connected to

Tray 2’s upper connector to the

connector on the back of the

printer.

18

Plug the black 3-pin connector of power

supply harness A (with the core

attached) into a black socket at the

back of the printer, and then plug the

power supply harness A’s white 2-pin

connector into the white PJ6 socket on

Tray 2’s unit.

The 3-pin connector (black) can

be plugged into any of the three

sockets on the printer. As an

example, the illustration at the

right shows the connector

plugged into the lower-left

connector.

Summary of Contents for magicolor 7300

Page 1: ...magicolor 7300 User s Guide 1800698 001A...

Page 8: ...Contents vi...

Page 9: ...1 Software Installation...

Page 17: ...2 Using Media...

Page 40: ...Loading Media 32 Envelopes Postcards...

Page 46: ......

Page 47: ...3 Working with the Printer...

Page 64: ......

Page 65: ...4 Working with the Printer Driver...

Page 75: ...5 Working with Color...

Page 82: ......

Page 83: ...6 Working with the Status Monitor...

Page 87: ...7 Replacing Consumables...

Page 126: ......

Page 127: ...8 Maintaining the Printer...

Page 133: ...9 Installing Accessories...

Page 172: ......

Page 173: ...10 Troubleshooting...

Page 218: ......

Page 219: ...A Technical Specifications...