Z Shaft Encoder

Introduction

The ability to place stitches precisely at high speed is dependent on the accurate

operation of the electronics and electromechanical assemblies. The "key" to this is

the Z encoder. The information provided to the CPU and other electronics by the Z

encoder is the basis for all the embroidery head activity.

The Z Encoder is a two channel quadrature output with index pulse. If you send the

output to an oscilloscope you will see two square wave signals, one slightly ahead

of the other. You will also see a third signal, the index pulse. The CPU interprets

these signals to determine position, speed, and head up.

The CPU uses this information to determine when to move the beam, when to stop

the head for a color change, when setting home position is allowed, how fast the

head is running, how many stitches have been embroidered, etc.

It is important to understand that the peripheral operational software handles the

motor control circuitry differently when the Z axis is running than it does when the

Z axis is stopped. When running, the motor control circuitry allows the X,Y, and Z

axis motors only minute errors in rotation. Any error greater than the allowed error

will cause the motor to be driven to eliminate the error. When the peripheral is

stopped however, the software that controls the Z motor allows a larger "window"

of error. The purpose of this window is to keep the motors from oscillating around

the null, hunting for absolute position.

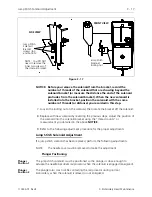

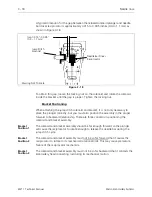

The green LED marked ZINDEX on the front of the peripheral (see Figure 3-4) can be

used to see if the CPU is in fact receiving a head up (or mark) pulse from the

encoder. (This indicates that the encoder and associated cables are functional.) It

should be noted however, that the ZINDEX (or "headup") LED does NOT have to be

lit when the peripheral is stopped, and the LED CANNOT be used to make a

determination of the Z encoder alignment status." If used in conjunction with the

proper headup tool, the LED can be used to see if the head up pulse is triggering

early or late as compared to absolute mechanical headup.

The procedures in the following pages will result in the most proper and accurate

alignment and repair of the Z encoder system that is possible and/or feasible in the

field by a technician.

It can be seen that the proper alignment of the Z encoder can result in maintaining

embroidery quality and proper machine operation. Slight Z encoder misalignment

can cause many kinds of erratic operation and/or intermittent thread breaks. A

larger misalignment can be the cause of equipment damage and subsequent

electronic or mechanical failures. The careful application of the Z encoder

procedures by a factory trained technician will result in a machine that will operate

correctly and reliably.

3 - 4

Z Shaft Encoder

EMT 1 Technical Manual

Melco Embroidery Systems