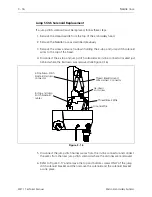

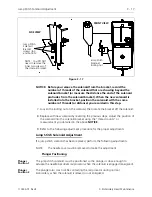

Hook Timing Adjustments Only

This procedure is for checking and setting hook timing adjustments when the hook

assembly is not being replaced. If you are replacing the hook assembly, refer to the

preceding section in this chapter. If you suspect your peripheral has gone out of

timing due to hitting a hoop, bird nesting, or some other reason, follow these steps:

1. Move the the table top to the lower position, or remove it and set it aside.

2. Remove the needle plate, both rotary hook covers, and the bobbin case.

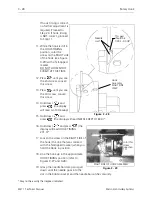

3. With the machine ON and ready for operation, press to switch to the

Service/Maintenance Menu. The peripheral LCD displays HEAD TIMING MENU.

4. Press and the LCD displays HEAD TIMING ON.

5. Refer to the Needle Depth procedure that immediate precedes this procedure

and perform the steps numbered 4 through 16, then return to Step 6 below.

6. Press keys. The head rotates to the ‘‘Head Up’’ position and the LCD

displays GO TO HEADUP 110.0*.

7. Hold down and press (the display will read NEEDLE DEPTH 180.0)*.

8. Hold down and press (the display will read HOOK TIMING 201.0)*.

9. Grasp the needle bar clamp and pull down until the needle goes into the slot in

the bobbin basket and the

needle bar catches securely.

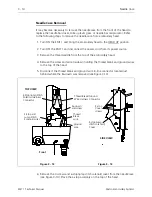

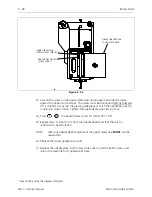

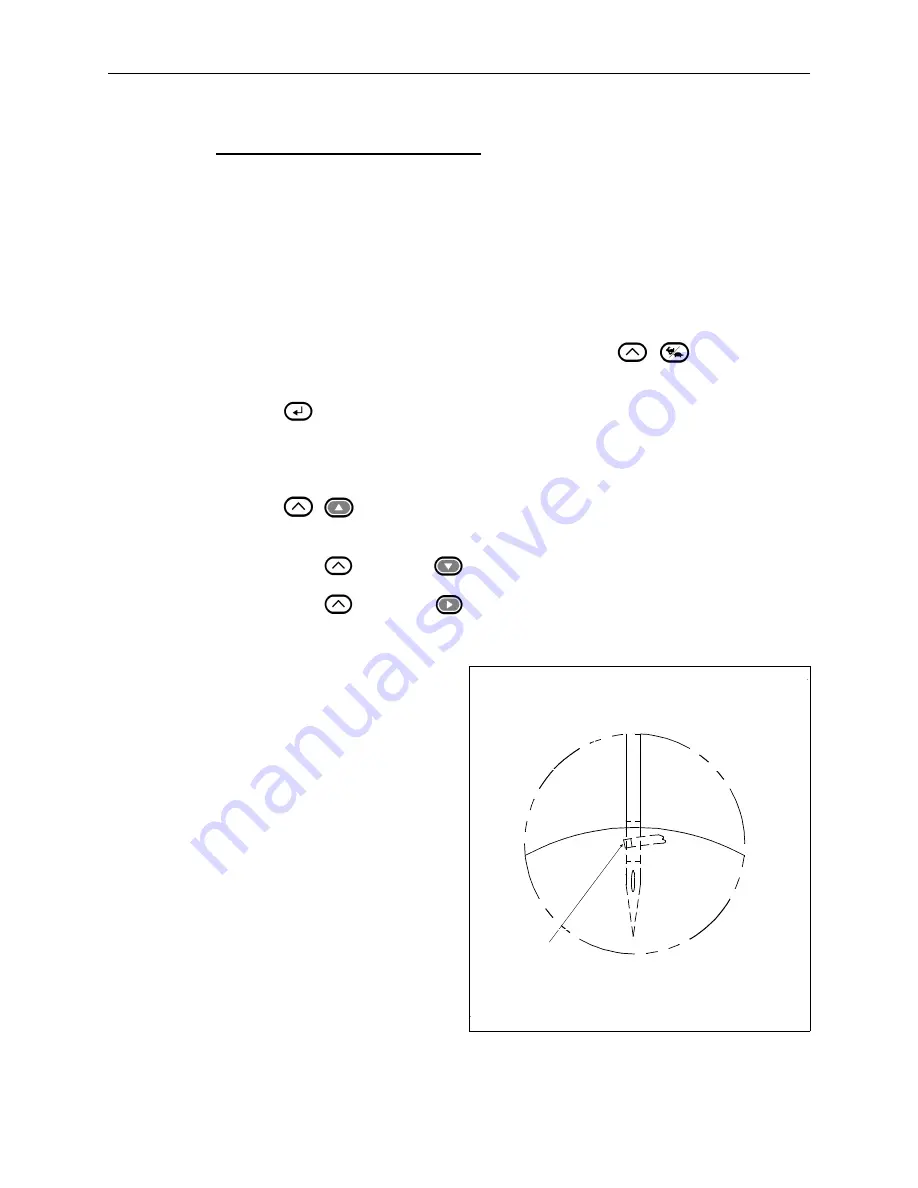

10. Check to see if hook timing is

correct before you proceed.

You must check the hook

point’s alignment with the

needle, and you must check

the gap. Refer to Figure 3-27

to check the alignment to the

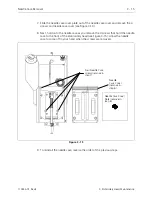

needle. Refer to Figure 3-28 to

check the gap; there should be

a 0.002" to 0.020" gap (about

the width of a thread) between

the needle and the hook point.

Since there is some variation

between the needles, check

needles 1, 5, and 10; ideally,

the smallest gap should be set

at 0.003".

* May not be exactly the degrees indicated.

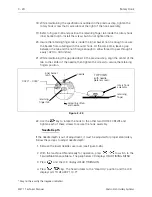

The hook

point should

be just visible

behind the

needle

If the hook

point does

not extend to

the needle, it

is referred to

as "retarded"

If the hook point

extends beyond

the needle, it is

referred to as

"advanced"

Figure 3 - 27

Hook Timing Adjustments Only

3 - 27

110344-01, Rev B

3. Embroidery Head Maintenance