Inspection

This procedure is a guide for determining the condition of the encoder.

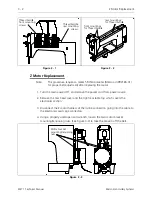

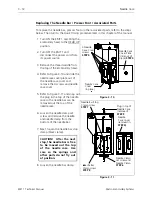

Inspect the Z shaft encoder following the steps below. If the requirements of this

process are not met, replace the encoder by following the Shaft Encoder Installation

procedure.

1. Switch the peripheral OFF, lower the table top, and remove the rear head cover.

2. When switched back on it is important that the computer not down load a

design to the peripheral. To insure this condition remove the network cable (or

boot disk if used).

3. With the network cable removed (or boot disk not inserted into the disk drive),

turn ON the embroidery peripheral.

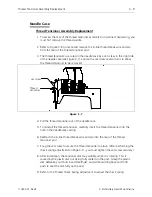

4. Locate the green LED marked "ZINDEX" on the front of the peripheral, above the

lowered table top (see Figure 3-4).

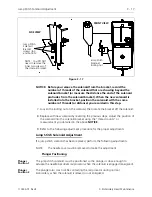

Or remove the card cage cover and locate the innermost LED on the top of the

CPU. Most likely this LED will not be glowing. It is only supposed to glow for a 1

degree duration each revolution of the Z shaft encoder.

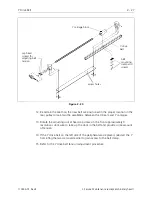

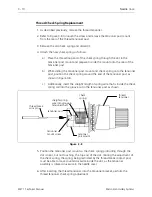

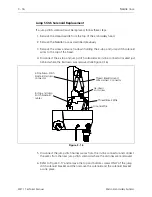

5. Rotate the embroidery head manually in a clockwise direction (when viewing

from the rear of the machine). This rotation can be performed by rotating the

shaft pulley that is driven by the motor belt (see Figure 3-5).

6. While slowly rotating the head, check that the green LED on the front or the

innermost LED on the CPU blinks once each revolution (this is the "index" or

"headup" mark).

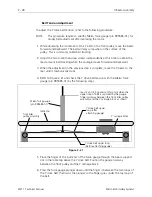

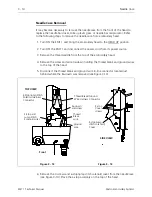

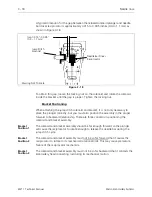

7. If there is no evidence of the LED blinking, inspect the electrical connectors

(encoder cable plug and encoder body) for loose wires, loose fits, and any visual

damage. Clean connections and/or replace components as necessary.

8. Rotate the head again to check for the blinking LED. If the "test" repeatedly fails

refer to the following installation procedure for a new Z shaft encoder.

Green LED

marked ZINDEX

Figure 3 - 4

Inspection

3 - 5

110344-01, Rev B

3. Embroidery Head Maintenance