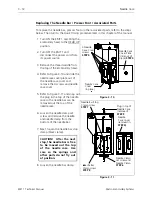

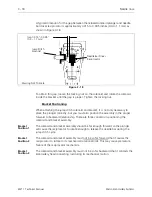

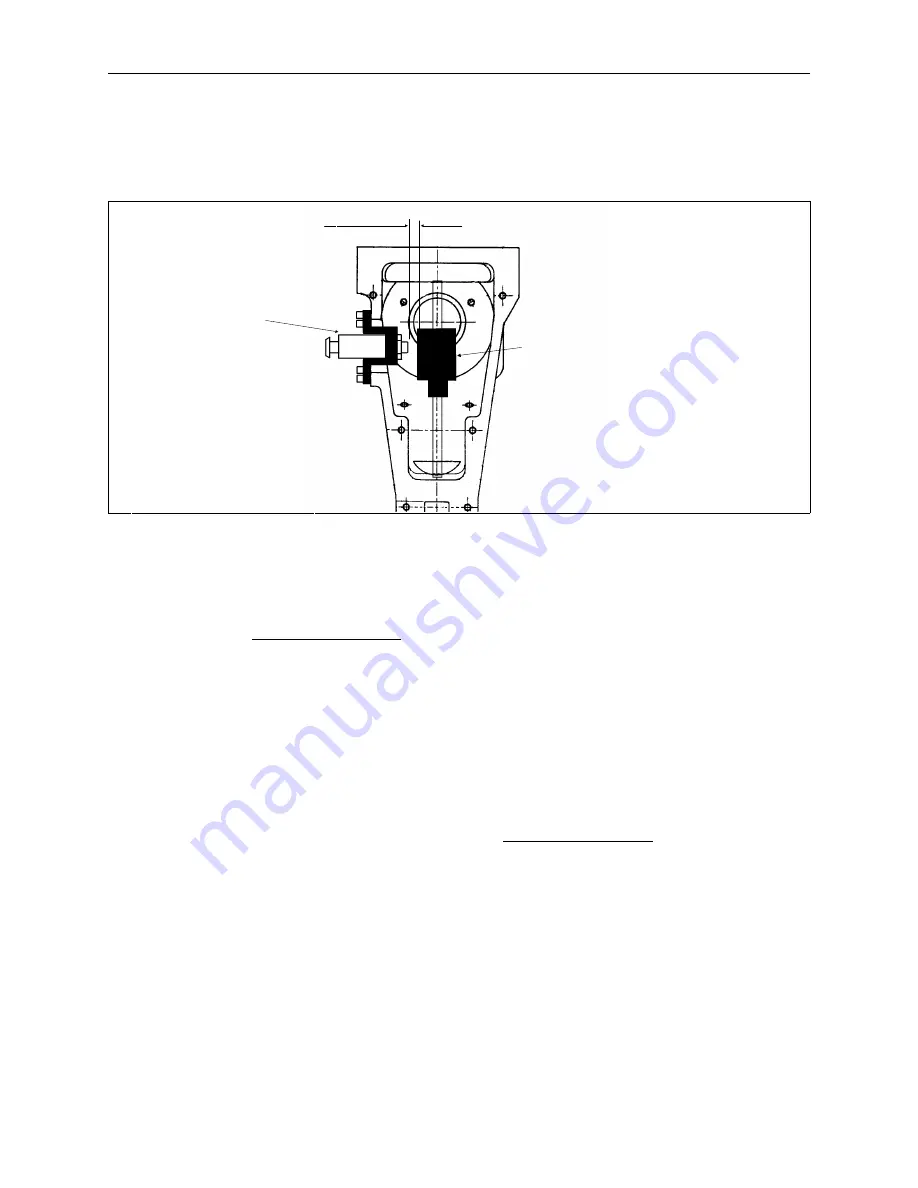

A typical dimension for the gap between the relaxed solenoid plunger and needle

bar driver reciprocator is approximately 0.015 to 0.045 inches (0.4 to 1.1 mm) as

shown in Figure 3-18.

To obtain this gap, loosen the locking nut on the solenoid and rotate the solenoid

inside the bracket until the gap is proper. Tighten the locking nut.

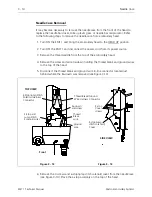

Bracket Positioning

When attaching the jump stitch solenoid and bracket, it is not only necessary to

place the plunger correctly, but you must also position the assembly in the proper

forward to backward relationship. There are three concerns in positioning the

solenoid and bracket assembly:

Bracket

Position 1

The solenoid and bracket assembly should be far enough forward so the plunger

will cause the reciprocator to rotate enough to release the needle bar during the

jump stitch cycle.

Bracket

Position 2

The solenoid and bracket assembly must not be so far forward that it causes the

reciprocator to rotate to its mechanical rotational limit. This may cause premature

failure of the reciprocator mechanism.

Bracket

Position 3

The solenoid and bracket assembly must not be so far backward that it contacts the

embroidery head connecting rod during its mechanical motion.

Needle Bar Driver

Reciprocator

Jump Stitch

Solenoid

Gap 0.015"- 0.045"

(0.4 - 1.1 mm)

Drawing Not To Scale

Figure 3 - 18

3 - 18

Needle Case

EMT 1 Technical Manual

Melco Embroidery Systems