3 - 12

2

1

2

1

CHECK

Lift truck environment

Carry out a general inspection around the lift truck:

-Fluid leaks or stains on the ground.

-Additional objects on the lift truck and in the cabin.

-Mounting and locking of the attachment.

-Mounting and adjustment of rear-view mirrors.

-Condition of the tyres, to detect cuts, blisters, wear, etc.

t

IMPORTANT

t

Follow the operator instructions (

e

1 - OPERATING AND SAFETY INSTRUCTIONS: OPERATOR INSTRUCTIONS).

CLEANLINESS OF THE FORKLIFT

-Cleanliness of lights and rear-view mirror.

-Excess dirt or build-up of material (e.g. straw, flour, sawdust, organic waste, etc.).

-On a daily basis, according to the conditions of use and the environment, the operator should ensure that the forklift

truck is kept in a clean condition.

-Particular attention should be paid to accumulations of flammable materials (e.g. straw, flour, sawdust, organic waste,

etc.) and fuel or lubricant leaks, as these significantly increase the risk of fire outbreaks.

-A regular inspection of the whole lift truck, especially the engine housing and the central part of the frame, is necessary

to see how frequently it needs to be cleaned to prevent these potential accumulations of material or leakages.

CHECK

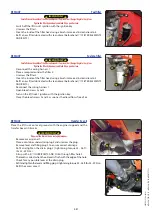

Engine oil level

Place the lift truck on level ground with the engine stopped, and let the oil settle in

the sump.

-Open the engine cover.

-Pull out dipstick 1.

-Clean the dipstick and check the correct level between the two notches.

- If necessary, add oil (

e

LUBRICANTS AND FUEL) through the filler hole 2.

- Visually check that there is no leakage or seepage.

CHECK

Cooling liquid level

Place the lift truck on level ground with the engine stopped, and allow the engine to cool.

t

IMPORTANT

t

To avoid any risk of spraying or scalding, wait until the engine has cooled down before removing the cooling system

filler plug.

In the event of an emergency, it is possible to use water as the coolant, but then proceed to drain the coolant circuit as

quickly as possible.

-Open the engine cover.

-The liquid must be at mid-height in the expansion tank 1.

-If necessary, add coolant (

e

LUBRICANTS AND FUEL) through the filler hole 2.

- Visually check that there is no leakage or seepage.

Ü

10H - DAILY SERVICE OR EVERY 10 HOURS OF SERVICE

647732

(31/10/2019)

MT

625

H

75K

ST5

S1

/ MT

625

H

75K

COMFORT

ST5

S1

Summary of Contents for MT 625 H 75K COMFORT ST5 S1

Page 6: ...1 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 7: ...1 3 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 13: ...1 9 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 21: ...1 17 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 33: ...1 29 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 39: ...2 1 2 DESCRIPTION 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 40: ...2 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 51: ...2 13 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 55: ...2 17 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 86: ...2 48 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 87: ...3 1 3 MAINTENANCE 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 123: ...3 37 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 126: ...3 40 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 128: ...4 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...