3 - 26

1

4

2

3

5

2

1

REPLACE Coolant

These operations are to be carried out as necessary or every 2 years at the beginning of

winter. Place the lift truck on level ground with the engine stopped and cold.

t

IMPORTANT

t

The engine does not contain any anti-corrosion elements and must be filled throughout the year with a mixture

containing 25% ethylene glycol-based antifreeze.

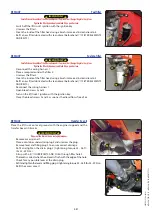

DRAINING THE LIQUID

-Open the engine cover.

-Remove access panel 5.

-Place a container under the radiator drain plug 1 and unscrew the plug.

-Remove filler plug 2 from the expansion tank and fully open the heating control

to ensure correct drainage.

-Let the cooling circuit drain entirely while ensuring that the ports do not get clogged.

-Check the condition of the hoses as well as the fastening devices and change the

hoses if necessary.

-Rinse the circuit with clean water and use a cleaning agent if necessary.

FILLING WITH COOLANT

-Refit and tighten the radiator drain plug 1 (tightening torque 15 ft-lbs ±1.5 ft-lbs

20 N.m ±2 N.m).

-Slowly fill the circuit with coolant (

e

LUBRICANTS AND FUEL) up to the middle of

the expansion tank 3 by the filler hole 4.

-Refit the filler plug 2.

-Run the engine at idle for a few minutes.

-Check for any possible leaks.

-Check the level and refill if necessary.

REPLACE

Dry air filter cartridge

In case of use in a heavily dust laden atmosphere, there are pre-filtration cartridges,

(

e

FILTER ELEMENTS AND BELTS). Also, the checking and cleaning periodicity of the

cartridge must be reduced (up to 250 hours in a very dusty atmosphere and with

pre-filtration).

t

IMPORTANT

t

Change the cartridge in a clean location, with the engine stopped. Never operate the lift truck with the air filter

removed or damaged.

-Open the engine cover.

-Loosen the locks and remove cover 1.

-Gently remove the cartridge 2 to reduce dust falling as far as possible.

-Leave the safety cartridge in place.

-Carefully clean the following parts with a damp, clean lint-free cloth.

• The inside of the filter and cover.

• The inside of the filter inlet hose.

• The gasket surfaces in the filter and in the cover.

-Check pipes and connections between the air filter and the engine and the connection and state of the clogging indicator

on the filter.

-Before fitting check the condition of the new cartridge (

e

FILTER ELEMENTS AND BELTS).

-Insert the cartridge in the filter axis and push the cartridge pressing against the outer edge and not the centre.

-Reassemble the cover, guiding the valve downwards.

647732

(31/10/2019)

MT

625

H

75K

ST5

S1

/ MT

625

H

75K

COMFORT

ST5

S1

Summary of Contents for MT 625 H 75K COMFORT ST5 S1

Page 6: ...1 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 7: ...1 3 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 13: ...1 9 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 21: ...1 17 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 33: ...1 29 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 39: ...2 1 2 DESCRIPTION 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 40: ...2 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 51: ...2 13 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 55: ...2 17 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 86: ...2 48 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 87: ...3 1 3 MAINTENANCE 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 123: ...3 37 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 126: ...3 40 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...

Page 128: ...4 2 647732 31 10 2019 MT 625 H 75K ST5 S1 MT 625 H 75K COMFORT ST5 S1...