The User Interface

125

Adjusting the P and Q ADC offset values

The following procedure may be used when setting the ADC offset values:

1.

Select an unused row in the Select Product to Setup screen and then select the Run option in the

Product Options screen

2.

Tap on the Learn icon in the Main Run screen to display the Learn options screen and select the

Setup option.

3.

In the Learn Setup screen, set the Head drive, Head RF gain, Head P gain and Head Q gain

options to Max. Then exit the screen and save the changes.

4.

Stop the conveyor and do not pass any product through the detector.

5.

Navigate to the PQ Analysis screen and monitor the P channel signal. The numbers will be

continually updating

6.

Observe the numbers and their sign to determine if the average movement is symmetrical about

zero (no adjustment required) or if it is biased in a positive or negative direction.

7.

If the bias is positive, enter a negative value in the P channel ADC offset field to bring the

movement back towards the target value of zero.

8.

If the bias is negative, enter a positive value in the P channel ADC offset field to bring the

movement back towards the target value of zero.

9.

Repeat the procedure for the Q channel.

Alternatively, you can use the EnviroScan screen to determine the offset values to use as follows:

1.

Select the P v Q tab in the EnviroScan screen.

2.

Allow the head to stabilise, then press the Reset button and allow the noise ball of the head to

build up.

3.

Note the average P and Q channel positive and negative values being displayed and use them to

determine the ADC offset values to enter in the PQ Analysis screen.

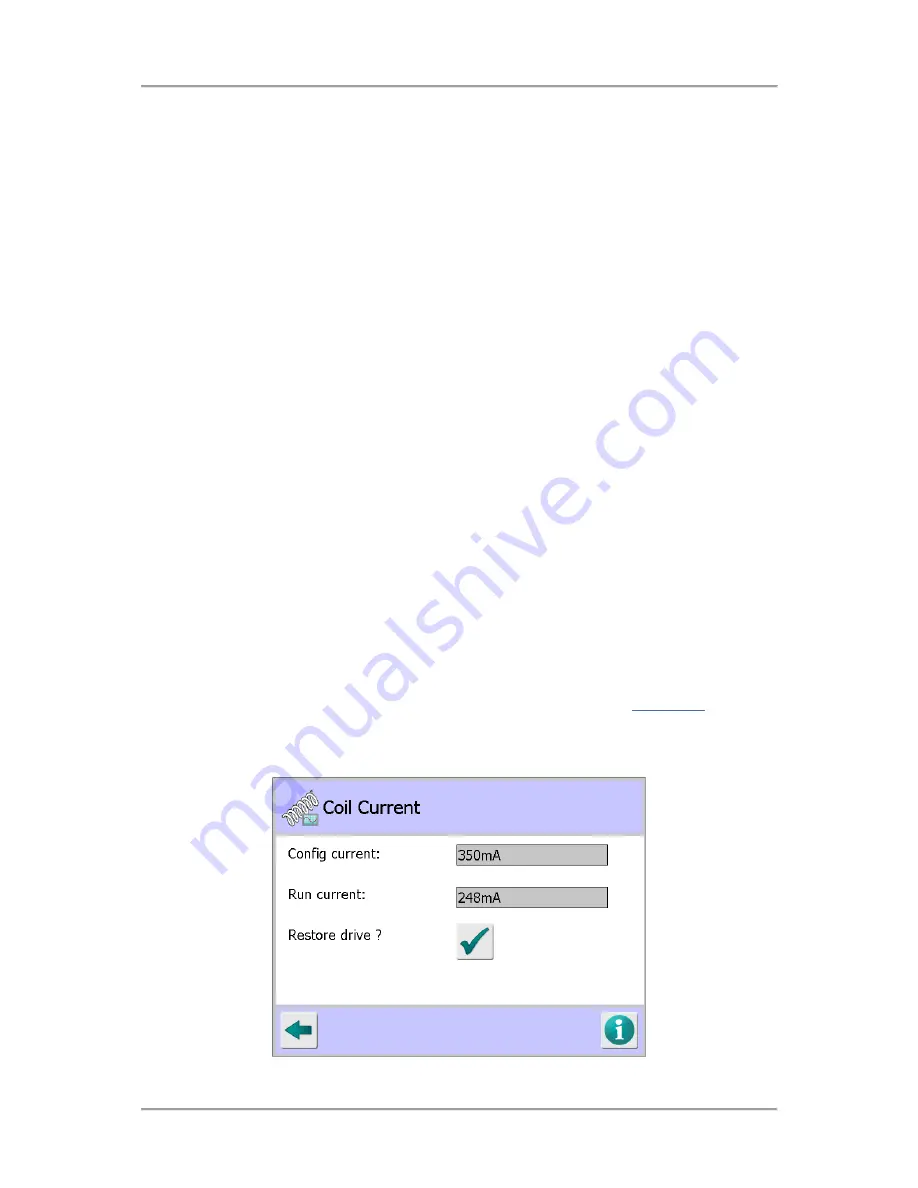

Coil Current

Purpose

The Coil Current screen is displayed by tapping on the Coil Current icon in the

Diagnostics

screen.

This screen is intended for advanced diagnostics use by Loma Service Engineers or Customer

Engineers only. It displays the configuration and run current values and can be used to restore the

drive for the frequency in use by the currently running product.

Summary of Contents for IQ3+

Page 2: ......

Page 36: ...Safety First 26 THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 43: ...Installation 33 ...

Page 60: ...Installation 50 THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 70: ...About the Metal Detector Range 60 THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 218: ...Operating Instructions 208 THIS IS PAGE INTENTIONALLY LEFT BLANK ...

Page 244: ...Maintenance 234 THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 248: ...Glossary 238 THIS PAGE IS INTENTIONALLY LEFT BLANK ...