FORM 160.54-O1

15

JOHNSON CONTROLS

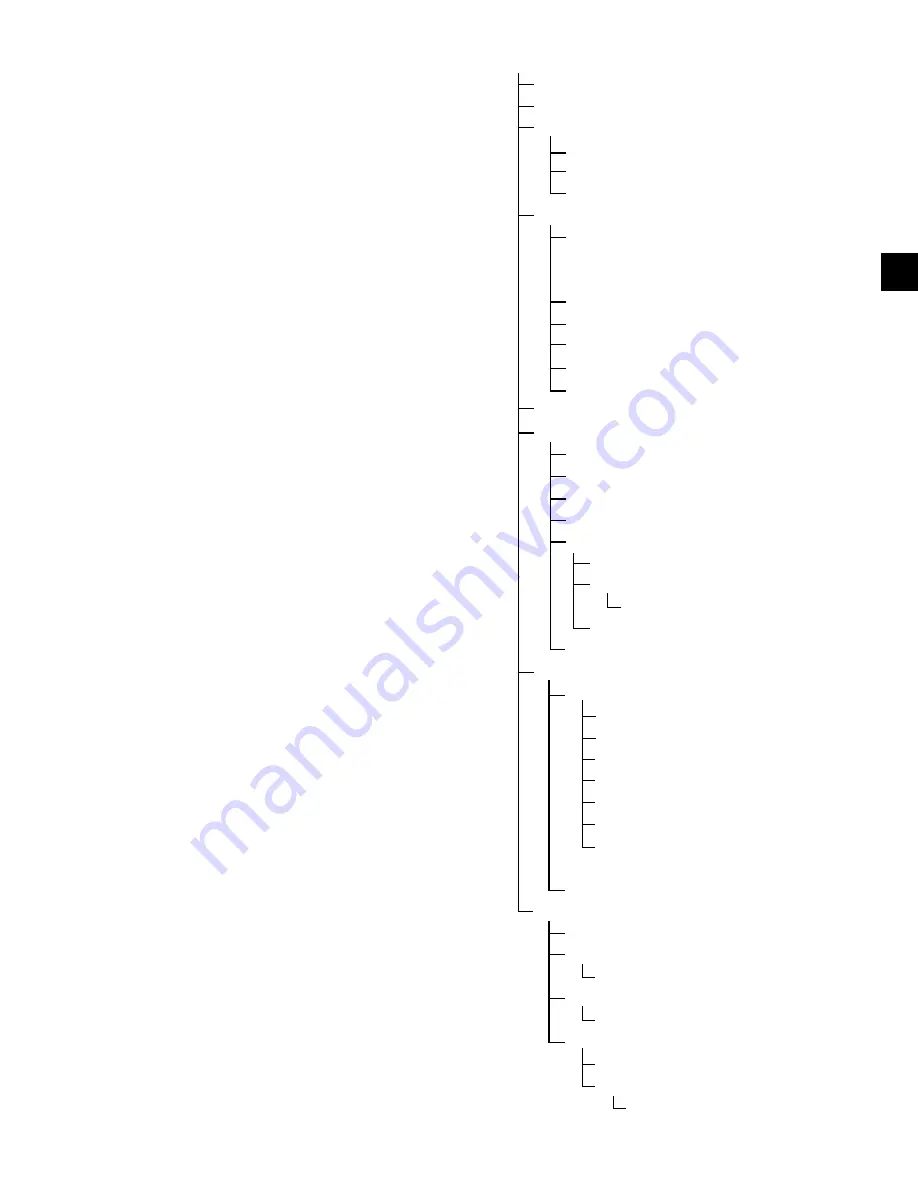

Home Screen (page 16)

System Screen (page 19)

Evaporator (page 21)

Condenser (page 24)

Level Control (page 24-31)

Heat Recovery (page 26)

Head Pressure Control (page 30)

Compressor (page 42)

Proximity Probe Calibration (Style E and earlier

chillers with G, H, or J compressors and Style F and

later chillers with J or H3 Compressors)(page 36)

Hot Gas Bypass (page 46)

Surge Protection Screen (page

48)

Variable Geometry Diffuser (page

52)

Vane Calibration (page 56)

VSD Tuning (page 58)

Oil Sump (page 60)

Motor (page 60)

EM Starter Version (page 64)

Mod “A” Solid State Starter (page 66)

Mod “B” Solid State Starter (page 68)

Medium Voltage Solid State Starter (page 70)

VSD (page 72)

VSD Details (page 76 78)

ACC Details (page 80, 82, 84)

Surge Map (page 86, 88)

Harmonic Filter Details (page 92, 94)

Motor Lubrication (page 96)

Setpoints (page 98)

Setup (page 100)

Schedule (page 106)

User (page 108)

Comms (page 110)

Printer (page 112)

Sales Order (page 114)

Operations (page 116)

Diagnostics

(Refer to YORK

Service Manual 160.54-M1)

Quick Start (page 104)

History (page 120)

History Details (page 120)

Security Log Screen (page 121)

Security Log Details Screen (page 122)

Custom View (page 123)

Custom Setup (page 124)

Trend (page 126)

Trend Setup (page 128)

Advanced Trend Setup (page 130)

Common Slots (page 132)

2.

If the dialog box begins with the word “ENTER”,

use the numeric keys to enter the desired value.

Leading zeroes are not necessary. If a decimal point

is necessary, press the ‘•’ key (i.e. 45.0).

Pressing the ▲ key, sets the entry value to the default

for that setpoint. Pressing the ▼ key, clears the pres

-

ent entry. The ◄ key is a backspace key and causes

the entry point to move back one space.

If the dialog box begins with “SELECT”, use the

◄ and ► keys to select the desired value.

If the previously defined setpoint is desired, press

the ‘X’ (Cancel) key to dismiss the dialog box.

3. Press the ‘

’ (Enter) key.

If the value is within range, it is accepted and the

dialog box disappears. The chiller will begin to op-

erate based on the new programmed value. If out of

range, the value will not be accepted and the user is

prompted to try again.

Manual Controls

Some keys are used to perform manual control func-

tions. These may involve manual control of items such

as the pre-rotation vanes, variable orifice or oil pump

speed. Other keys in this category are used to initiate/

terminate processes such as calibrations or reports.

Free Cursor

On screens containing many setpoints, a specific “soft”

key may not be assigned to each setpoint value. A soft

key will be assigned to enable the cursor arrow keys

below the numeric keypad which are used to “highlight”

the desired setpoint field. At this point, the ‘

’ key is

pressed to bring up a dialog prompting the user to enter

a new setpoint value. The ‘X’ key cancels cursor mode.

(See the Schedule Screen for an example.)

NaVigatioN

In order to maximize the amount of values which the

panel can display to the user, and in order to place those

values in context, multiple screens have been designed to

describe the chiller operation. In order to move from one

screen to the next, navigation keys have been defined.

These keys allow the user to either move “forward” to

a sub-screen of the present screen, or move “backward”

to the previous screen. Except for the Home Screen

display, the upper-right “soft” key will always return

the user to the Home Screen. Navigating with “soft”

keys is as simple as pressing the key next to the label

containing the name of the desired screen. The system

will immediately refresh the display with the graphics

for that screen. Following is a layout of all the screens

and how they are connected.

2

Summary of Contents for YORK YK MaxE

Page 10: ...JOHNSON CONTROLS 10 FORM 160 54 O1 OptiView Control Center THIS PAGE INTENTIONALLY LEFT BLANK...

Page 17: ...FORM 160 54 O1 17 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 59: ...FORM 160 54 O1 59 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 65: ...FORM 160 54 O1 65 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 79: ...FORM 160 54 O1 79 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 91: ...FORM 160 54 O1 91 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 105: ...FORM 160 54 O1 105 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 113: ...FORM 160 54 O1 113 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 123: ...FORM 160 54 O1 123 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 133: ...FORM 160 54 O1 133 JOHNSON CONTROLS 2 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 166: ...JOHNSON CONTROLS 166 FORM 160 54 O1 Printers...