SECTION 3 - CHASSIS, PLATFORM, & SCISSOR ARMS

31215923

3-21

NOTE:

Make sure the retaining ring is securely seated in the

groove.

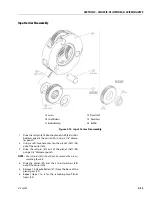

10. Place retaining ring (1I) over the spacer onto spindle

(1A) in hub (1G).

11. At this point the hub-spindle sub-assembly is com-

plete.

Main Assembly

BEWARE OF SHARP EDGES IN COUNTERBORE WHEN INSTALLING THE

O-RING.

1. Grease O-ring (5) and place it into the counterbore in

hub (1G).

NOTE:

O-ring may be stretched or pinched together to

make it fit the counterbore exactly.

2. Oil all exposed surfaces inside hub (1G).

3. Place internal gear (2) into hub (1G) so that its inter-

nal splines mesh with the external splines of spindle

(1A). Oil internal gear (2).

Summary of Contents for ERT2669

Page 2: ......

Page 4: ...INTRODUCTION A 2 31215923 REVISON LOG Original Issue A January 08 2021...

Page 12: ...viii 31215923 TABLE OF CONTENTS...

Page 40: ...SECTION 1 SPECIFICATIONS 1 22 31215923...

Page 58: ...SECTION 2 GENERAL 2 18 31215923...

Page 187: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 31215923 4 11...

Page 206: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 4 30 31215923...

Page 225: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 31215923 4 49...

Page 242: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 4 66 31215923...

Page 307: ...SECTION 5 JLG CONTROL SYSTEM 31215923 5 65...

Page 334: ...SECTION 6 LSS SETUP CALIBRATION SERVICE 6 12 31215923...

Page 362: ...SECTION 7 GENERAL ELECTRICAL INFORMATION SCHEMATICS 7 28 31215923...

Page 374: ...SECTION 7 GENERAL ELECTRICAL INFORMATION SCHEMATICS 7 40 31215923...

Page 375: ......