SECTION 5 - JLG CONTROL SYSTEM

31215923

5-5

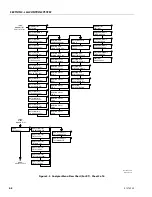

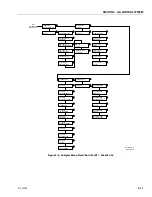

System Fault/DTC Indication

The Platform Control Box displays DTC texts. DTC flash

codes are indicated by the number of flashes and

pauses of the System Fault indicator on the face of the

platform control box.

For more information on DTCs and flash code descrip-

tions, refer to Figure 5.2, Analyzer Menu Flow Chart (For

RT) & Figure 5.3, Analyzer Menu Flow Chart (For ERT).

IT IS A GOOD PRACTICE TO AVOID PRESSURE-WASHING ELECTRICAL/

ELECTRONIC COMPONENTS. SHOULD PRESSURE-WASHING BE UTI-

LIZED TO WASH AREAS CONTAINING ELECTRICAL/ELECTRONIC COM-

PONENTS, JLG INDU STRIES, INC. RECOMMENDS A MA XIMUM

PRESSURE OF 750 PSI (52 BAR) AT A MINIMUM DISTANCE OF 12

INCHES (30.5 CM) AWAY FROM THESE COMPONENTS. IF ELECTRICAL/

ELECTRONIC COMPONENTS ARE SPRAYED, SPRAYING MUST NOT BE

DIRECT AND BE FOR BRIEF TIME PERIODS TO AVOID HEAVY SATURA-

TION.

Summary of Contents for ERT2669

Page 2: ......

Page 4: ...INTRODUCTION A 2 31215923 REVISON LOG Original Issue A January 08 2021...

Page 12: ...viii 31215923 TABLE OF CONTENTS...

Page 40: ...SECTION 1 SPECIFICATIONS 1 22 31215923...

Page 58: ...SECTION 2 GENERAL 2 18 31215923...

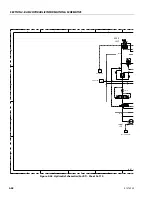

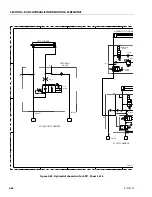

Page 187: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 31215923 4 11...

Page 206: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 4 30 31215923...

Page 225: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 31215923 4 49...

Page 242: ...SECTION 4 BASIC HYDRAULIC INFORMATION SCHEMATICS 4 66 31215923...

Page 307: ...SECTION 5 JLG CONTROL SYSTEM 31215923 5 65...

Page 334: ...SECTION 6 LSS SETUP CALIBRATION SERVICE 6 12 31215923...

Page 362: ...SECTION 7 GENERAL ELECTRICAL INFORMATION SCHEMATICS 7 28 31215923...

Page 374: ...SECTION 7 GENERAL ELECTRICAL INFORMATION SCHEMATICS 7 40 31215923...

Page 375: ......