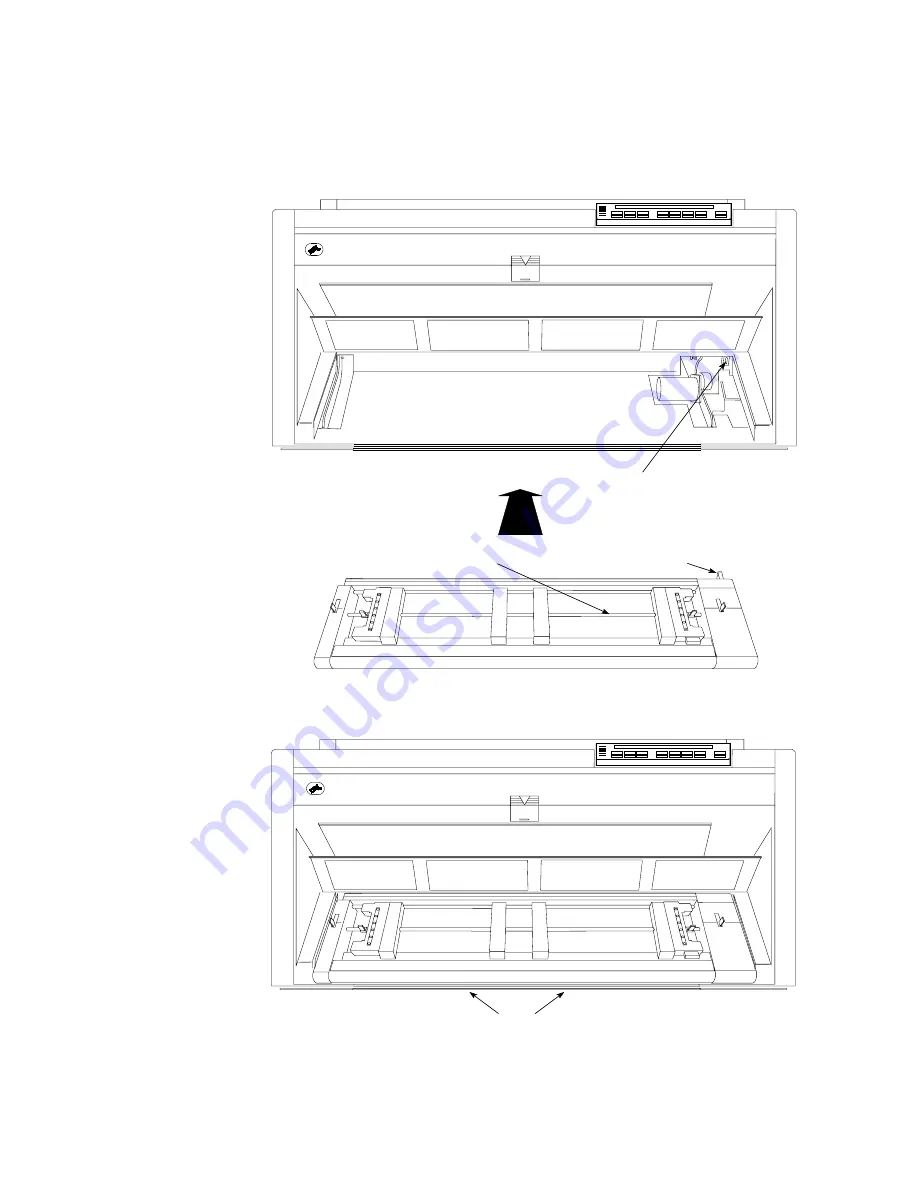

6. With both hands supported on the round tractor shaft, gently push the tractor

unit upward until it clicks on both sides, the electrical connector tab is fully

seated in the connector, and the bottom of the tractor unit is level with (same

amount of space from) the base of the printer.

F r o n t

T r a c t o r

E l e c t r i c a l

C o n n e c t o r

E l e c t r i c a l

C o n n e c t o r

T a b

R o u n d

T r a c t o r

S h a f t

B a s e

17-80

001, 002 User’s Guide

Summary of Contents for 4247 - Model 001 B/W Dot-matrix Printer

Page 1: ...4247 Printer Models 001 002 IBM User s Guide SA24 4408 01 ...

Page 2: ......

Page 3: ...4247 Printer Models 001 002 IBM User s Guide SA24 4408 01 ...

Page 12: ...x 001 002 User s Guide ...

Page 16: ...xiv 001 002 User s Guide ...

Page 20: ...xviii 001 002 User s Guide ...

Page 22: ... 1 2 001 002 User s Guide ...

Page 26: ...1 6 001 002 User s Guide ...

Page 48: ...1 28 001 002 User s Guide ...

Page 66: ...2 2 001 002 User s Guide ...

Page 106: ...5 2 001 002 User s Guide ...

Page 108: ...6 2 001 002 User s Guide ...

Page 124: ...7 16 001 002 User s Guide ...

Page 200: ...10 20 001 002 User s Guide ...

Page 226: ...12 2 001 002 User s Guide ...

Page 228: ...13 2 001 002 User s Guide ...

Page 230: ...14 2 001 002 User s Guide ...

Page 234: ...15 4 001 002 User s Guide ...

Page 236: ...16 2 001 002 User s Guide ...

Page 344: ...18 6 001 002 User s Guide ...

Page 350: ...18 12 001 002 User s Guide ...

Page 398: ...20 32 001 002 User s Guide ...

Page 402: ...A 4 001 002 User s Guide ...

Page 432: ...B 12 001 002 User s Guide ...

Page 440: ...C 8 001 002 User s Guide ...

Page 450: ......

Page 453: ......