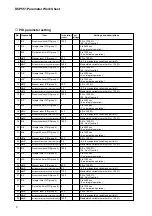

6

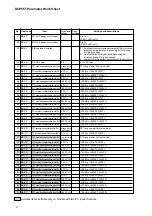

DCP551 Parameter Work Sheet

Event

Meaning

Setting

Operation

Auxiliary settings

type

category

category

24 to 63 Event off

-----

-----

Auxiliary 1

: None

Auxiliary 2

: None

64

Normal PV1 upper limit operation

Measuring instrument

PV

Auxiliary 1

: Hysteresis

Auxiliary 2

: Operating point

65

Normal PV1 lower limit operation

66

Normal PV2 upper limit operation

67

Normal PV2 lower limit operation

68

PV upper limit

69

PV lower limit

70

Deviation upper limit

71

Deviation lower limit

72

Deviation upper limit with standby

73

Deviation lower limit with standby

74

Absolute value deviation upper limit

75

Absolute value deviation lower limit

76

Absolute value deviation upper limit with standby

77

Absolute value deviation lower limit with standby

78

PV deviation rate upper limit

Measuring instrument

PV

Auxiliary 1

: Sampling cycle

Auxiliary 2

: Operating point

79

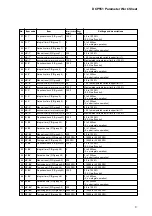

PV deviation rate lower limit

80

SP upper limit

Measuring instrument

PV

Auxiliary 1

: Hysteresis

Auxiliary 2

: Operating point

81

SP lower limit

82

MV upper limit

83

MV lower limit

84

SOAK absolute value deviation upper limit

85

SOAK absolute value deviation lower limit

86

SOAK absolute value deviation upper limit with standby

87

SOAK absolute value deviation lower limit with standby

88

Program No. binary code

Measuring instrument

Code

Auxiliary 1

: No. of output

Auxiliary 2

: None

89

Segment No. binary code

90

Program No. BCD code

91

Segment No. BCD code

92

Specified segment

Measuring instrument

Mode

Auxiliary 1

: Segment specification

Auxiliary 2

: None

93

RAMP-E monitoring time

Measuring instrument

Time

Auxiliary 1

: Operating point

Auxiliary 2

: None

94

Segment time

Measuring instrument

Time

Auxiliary 1

: On-time

Auxiliary 2

: OFF-time

95

Program time

96

PV1-PV2 differential upper limit

Measuring instrument

PV

Auxiliary 1

: None

Auxiliary 2

: Operating point

during CH switching

97

PV1-PV2 differential lower limit

during CH switching

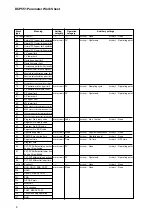

98

PV1-PV2 differential upper limit

Measuring instrument

PV

Auxiliary 1

: Hysteresis

Auxiliary 2

: Operating point

99

PV1-PV2 differential lower limit

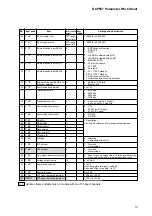

100 to 127

Event off

-----

-----

Auxiliary 1

: None

Auxiliary 2

: None

128

RUN, HOLD, END, FAST

Measuring instrument

Mode

Auxiliary 1

: None

Auxiliary 2

: None

129

HOLD

130

READY, READY FAST

131

END

132

G.SOAK wait

133

MANUAL

134

AT executing

135

FAST, READY FAST

136

Console setting operation

137

RUN