Chapter 12. CALIBRATION

This chapter covers the field calibrations procedures for the inputs, outputs and various functions of the DCP551

mark II controller after shipment from the factory. When calibration is made in the field, the original factory data is

erased, and so the specified input/output accuracies of the controller cannot be assured. This manual is for users who

are conversant with DCP551 mark II use and operation.

■

Precautions before calibration

Apply power and allow the controller to warm up for 2 hours before you calibrate the

DCP551 mark II. Confirm that the test equipment needed for calibration has stabilized.

Factory calibration has been made at a stable temperature of 23.0

°

C (±2

°

C). Calibrate

the DCP551 mark II in this range, and where there are no significant fluctuations in air

temperature.

You must write newly calibrated data to EEPROM before exiting from calibration

mode, otherwise all new data will be lost.

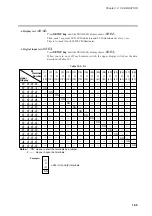

If calibration equipment of a lower grade than specified below is used, calibration

results may be unsatisfactory.

■

Equipment needed

1. Standard input source with ±0.02% accuracy (having more than 5 effective digits

and capable of generating both voltage and current outputs)

2. Decade resistance box with ±0.02% accuracy (having a range of 10 to 300

Ω

with a

resolution of more than 0.01

Ω

)

3. Digital ammeter with ±0.02% accuracy (measurable in the range of 4 to 20mA with

assured resolution of more than 0.01mA)

4. Thermometer with ±0.1

°

C accuracy (resolution of more than 0.1

°

C)

12-1