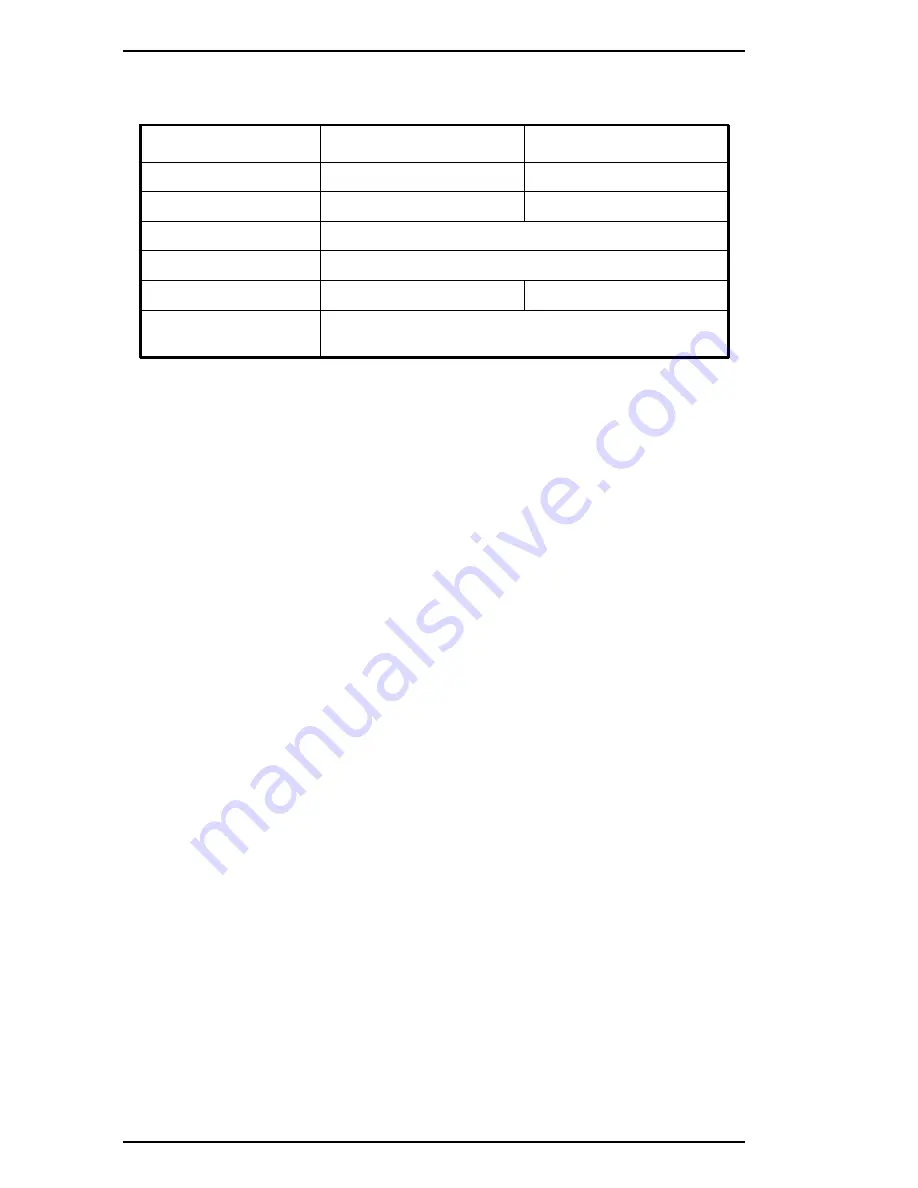

1.2.2 Electrical Specifications

Table 1-5. Electrical Requirements and Ranges

Description

100 V Version

200 V Version

Rated voltage

100

∼

120 VAC

220

∼

240 VAC

Input voltage range

90

∼

132 VAC

198

∼

264 VAC

Rated frequency range

50

∼

60 Hz

Input frequency range

47

∼

63 Hz

Power consumption

Less than 500 W

Less than 600 W

Power consumption while in

standby mode

Less than 15 W

(without option)

1.2.3 Reliability Specifications

MPBF (Mean Prints Between Failures): Over 25,000 sheets

Note:

MPBF indicates average number of pages printed before occurrence of problem requiring

replacement or service.

MTBF (Mean Time Between Failures):

3000 power on hours (POH)

Jam rate:

1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

Feed failure:

1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

Multiple paper feeds:

1 out of 500 sheets or less

Paper curl height:

30 mm (1.2 inches) or less

Leading edge bending (1 cm or more):

1 out of 1,000 sheets

MTTR (Mean Time To Repair):

30 minutes or less

Durability:

5 years or 180,000 sheets

1.2.4 Environmental Conditions for Operation (Including Imaging Cartridge)

Temperature:

10 to 35

°

C (50 to 95

°

F)

Humidity:

15 to 85% RH

Altitude:

2,500 m (8,200 feet) or lower

Levelness:

1

°

Illuminance:

3,000 lux or less (Must not be exposed to direct sunlight.)

Surrounding space:

Printer should have at least 100 mm of clearance on its

sides and rear.

1.2.5 Environmental Conditions for Storage and Transportation

Temperature:

0 to 35

°

C (32 to 95

°

F)

Humidity:

30 to 85% RH

Drop test:

Clear to JIS Z0200-1987 Level 1

Vibration:

Vibration frequency

5 to 100 Hz and 100 to 5 Hz

Acceleration

1 G

Acceleration direction

3 direction

Resistance to atmospheric pressure:

More than 61.3 KPa

Storage life:

18 months (following date of manufacture)

General Description

EPL-5500 Service Manual

1-6

Rev. B

Summary of Contents for EPL-5500

Page 1: ...EPSON TERMINAL PRINTER EPL 5500 SERVICE MANUAL EPSON 4005431 ...

Page 2: ... ii ...

Page 12: ...Rev A 1 iii ...

Page 62: ...EPL 5500 Service Manual Operating Principles Rev B 2 11 ...

Page 122: ...6 ii Rev A ...

Page 125: ...EPL 5500 Service Manual Maintenance Rev B 6 3 ...

Page 142: ...Figure A 8 C169 MAIN B Component Layout Rear EPL 5500 Service Manual Appendix Rev A A 17 ...

Page 144: ......

Page 145: ...EPSON ...