Appendix

EFORT INTELLIGENT EQUIPMENT CO.,LTD

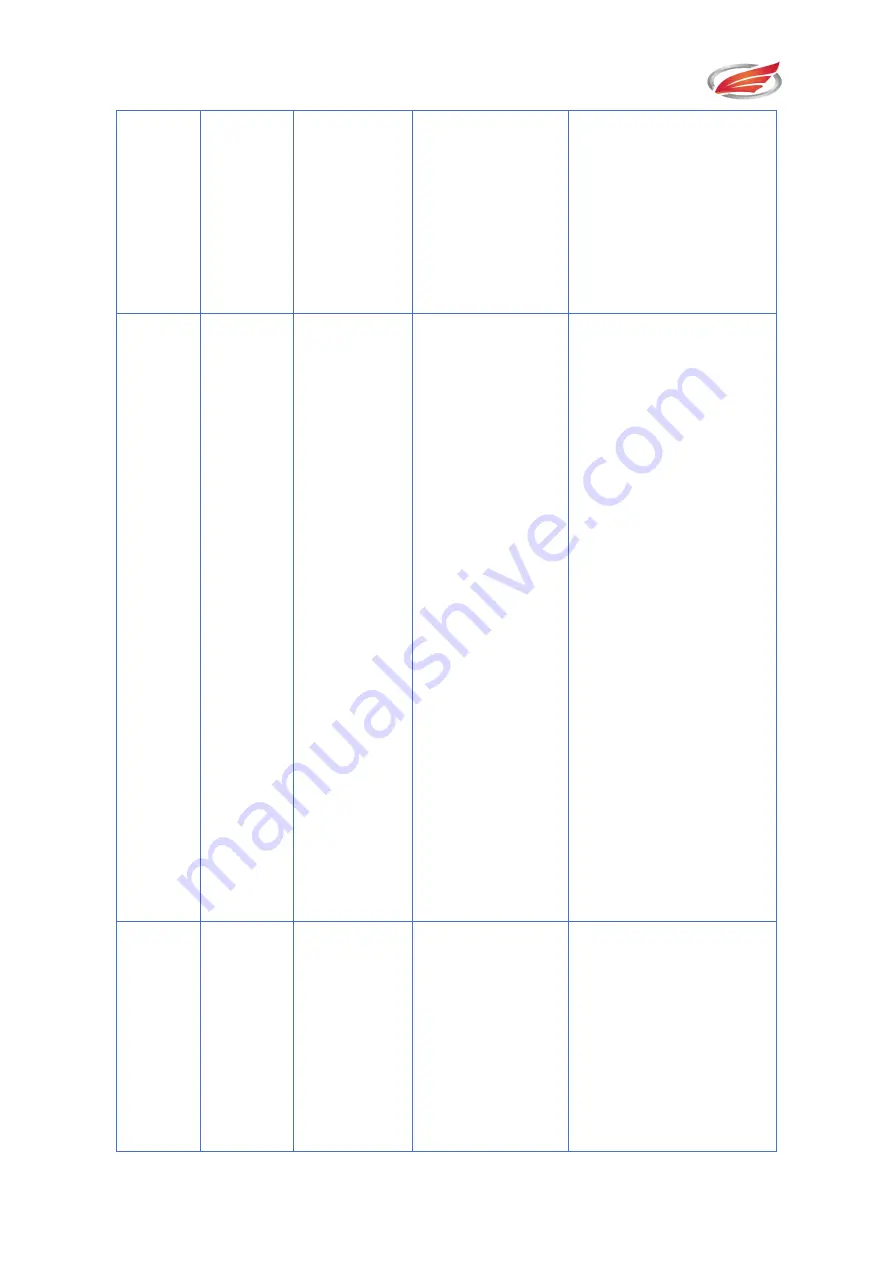

283

4951

0x220000

00

Arc welding:

After the arc

is broken, try

to retreat and

start the arc

again.

Restart the broken

arc. After the arc

is broken, the

robot will retreat

for a certain

distance and

restart the arc.

Wait for the robot to

process it automatically.

4952

0x220000

00

Arc welding:

Failure in

loading

configuration

file,

code: %d.

The configuration

file in the

controller is

missing, causing

the configuration

file to fail to read.

Reconfigure the

parameter file on the

robot teach pendant

interface and save it.

Code 0: fail to load the

welding machine setting

file;

Code 1: fail to load the

welding parameter file;

Code 2: fail to load the

device setting file;

Code 3: fail to load

current characteristic file;

Code 4: fail to load

voltage characteristic file;

Code 5: fail to load the

pendulum arc file;

Code 6: fail to load the

arc trace file.

4953

0x220000

00

Arc welding:

Move the

robot to the

vicinity of

the fault

point before

starting the

fault.

Before the fault

starts, the distance

between the end

of the robot and

the fault point

exceeds the set

distance.

1. Move the robot to the

vicinity of the fault point;

2. Set a reasonable

distance range.