Monitor

EFORT INTELLIGENT EQUIPMENT CO.,LTD

235

]

Bus_Get[78]-[79]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[17

]

Bus_Get[80]-[81]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[18

]

Bus_Get[82]-[83]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[19

]

Bus_Get[84]-[85]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[20

]

Bus_Get[86]-[87]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[21

]

Bus_Get[88]-[89]

FLOAT

2

FLOAT

Corresponding to

fidbus.eip_wo_r[22

]

Bus_Get[90]-[91]

FLOAT

4

FLOAT

Corresponding to

fidbus.eip_wo_r[23

]

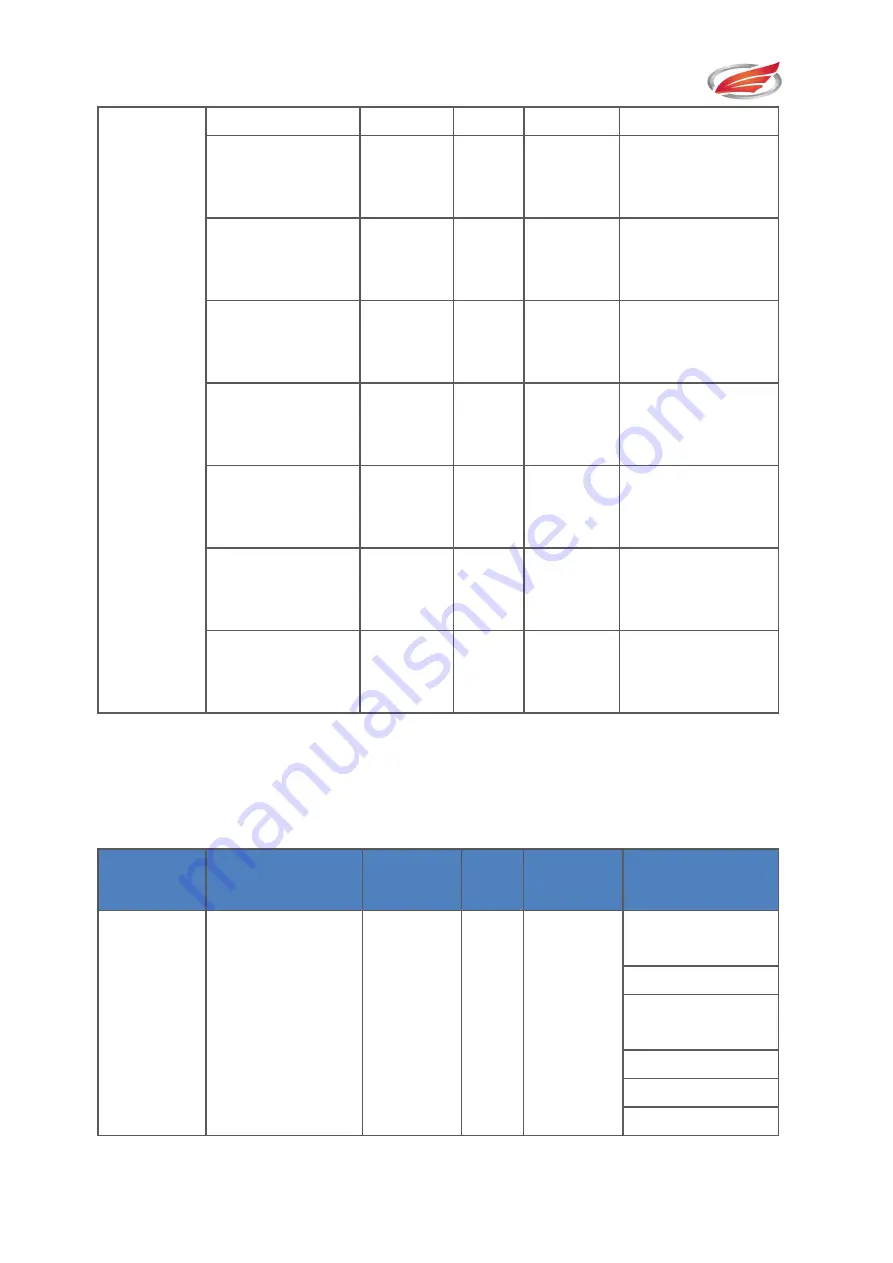

From Robot to PLC

In signal transport from Robot to PLC, the PLC is as receiving end, and the robot is

as sending end. Data sent mainly include the system variables and the TPU

variables, where the Bus_Set[0]-Bus_Set[191] is 192 Byte as the data sending.

Table 7-10 The data sending protocol of Ethernet/IP

Variable

Type

Physical Address

Unit

Bytes

Sub-Unit

Remark

System Va

riable

Bus_Set[0]

I16

1

BOOL

Bit0: Manual mo

de

Bit1: Auto mode

Bit2: Remote con

trol

Bit3: Servo status

Bit4: Alarm

Bit5: Emergency