CD800 Card Printer User’s Guide

17

User Button and Light

The

printer’s

U

SER

button

displays

with

a

border

of

light

that

indicates

the

system

status.

Use

the

U

SER

button

to:

•

Suspend

printer

activity—press

the

U

SER

button

when

the

LCD

panel

displays

Ready

.

•

Clear

a

message—press

the

U

SER

button

once.

•

Clear

all

messages—press

the

U

SER

button

for

2

seconds

or

more.

•

Clear

all

cards

currently

printing—press

and

hold

the

U

SER

button

for

2 seconds

or

more.

(Make

sure

that

this

action

is

allowed

in

your

card

system.)

•

Determine

whether

the

printer

is

ready,

busy

printing,

or

not

available.

Indicators

include

the

following:

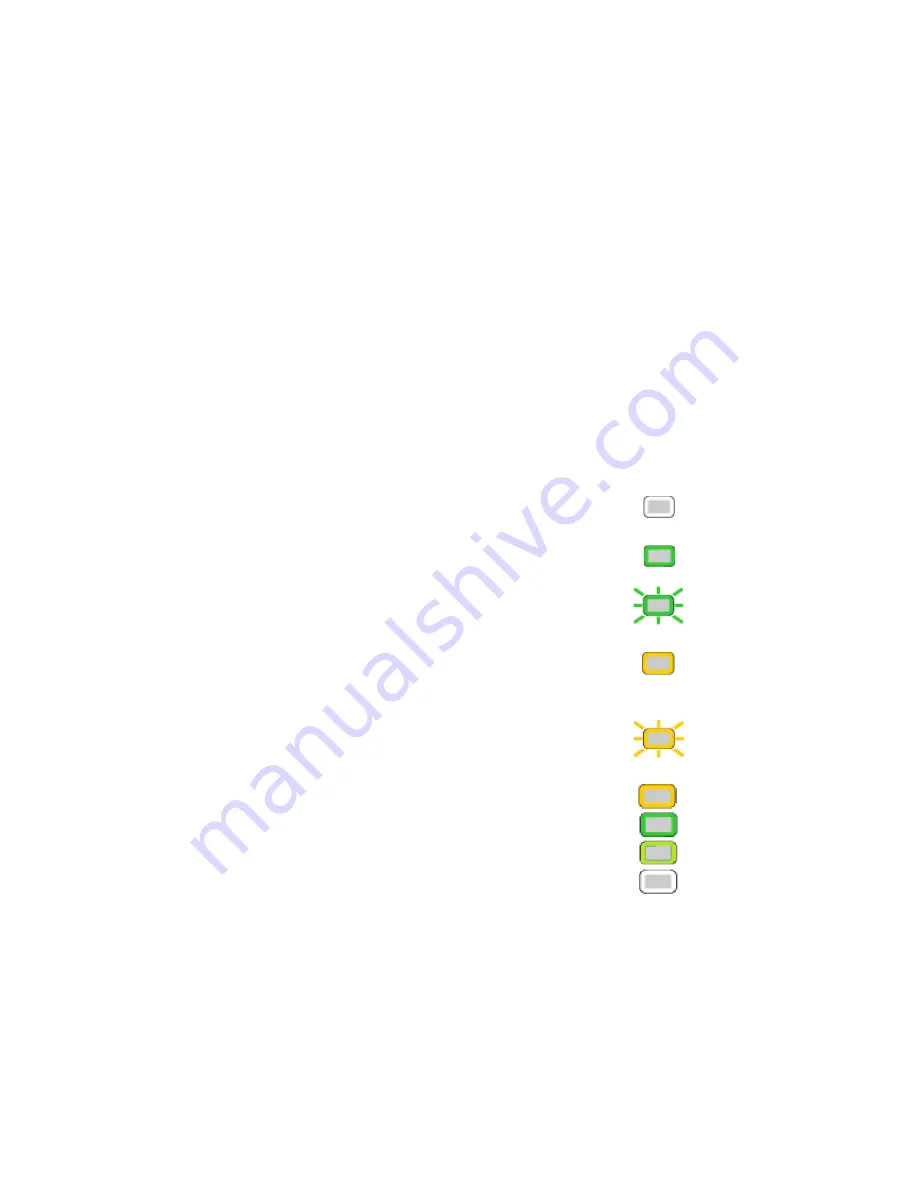

Off

The printer is off or suspended.

Green

The printer is ready.

Blinking green

The printer is busy.

Amber

The printer is not ready.

The P

OWER

button was pressed

to turn the printer off.

Blinking amber

The printer has an error.

Color Cycle:

Amber, Green,

Light Green, Off

The system is not ready or a

door on the system is open.

The colors cycle quickly.

Close and Lock Doors

displays

on the LCD panel if no other

message is present.

Summary of Contents for CD800

Page 1: ...Datacard CD800 Card Printer User s Guide March 2014 Part No 527443 001 Rev A ...

Page 8: ...viii ...

Page 14: ...xiv ...

Page 16: ...2 Introduction ...

Page 25: ...CD800 Card Printer User s Guide 11 ...

Page 26: ...12 About the Printer ...

Page 42: ...28 Printing Cards ...

Page 54: ...40 System Maintenance ...

Page 114: ...A 16 CLM Laminator ...