2. Installation

- 5 -

2.2 Product Configuration

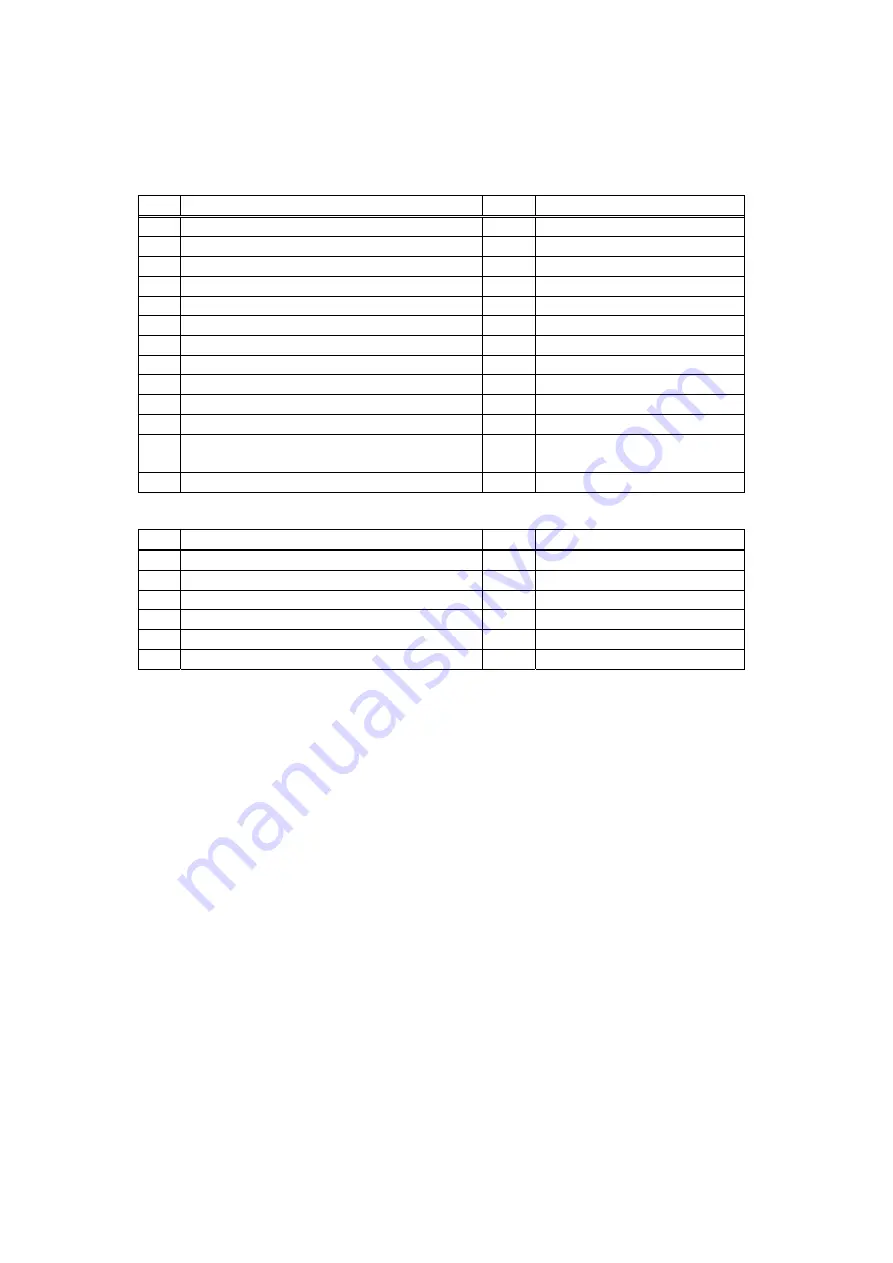

(1) Product Configuration List

1) CXDI-40G COMPACT

No. Item

Name Qty

Remarks

1

CXDI-40G COMPACT Imaging Unit

1

2 Sensor

cable

1 7m

3 Ready

lamp

1

4

Ready lamp mounting shaft

1

5 Insulation

sheet

16

6 Cable

tie

3

7 Screw

(M3x8mm)

4

8

Operation manual (For imaging unit)

-

9

Attached documents for medical

-

(JPN)

10 Warranty

registration

- (JPN)

11 Warranty

card

- (US)

12

Safety Booklet for German (WEEE

directive)

- (EU)

13 Installation

Report

- (US/EU)

2) CXDI SYSTEM III

No. Item

Name Qty

Remarks

1 Power

Box

1

2

X-ray I/F cable

1

20m

3

Power supply cable (with AC plug)

1

3m (100/120/230V)

4 Cable

clamp

1

5 Screw

(M4x6mm)

1

6

Operation manual (Power box)

-

LAN cable for connecting Control PC / Power Box and Network switch (Switching HUB) for

connecting the multiple Imaging Units shall be procured at each sales company.

- LAN cable (Over category 5)

Recommended length of the cable is 30m or less.

When Control PC and Power Box are connected directly, Cross type is used, but when they

are connected via Network switch, Straight type is used. However, this is not applied when

Network switch has AUTO-MDI/MDI-X function*.

- Network switch (Switching HUB)

Sales companies adopt Network switch (Switching HUB) after conducting the test and the

operation check for Switching HUB that meets the general standard.

Summary of Contents for CXDI-40G COMPACT

Page 24: ...2 Installation 4 2 CXDI SYSTEM III Assembly Packaging Accessories Box Power Box ...

Page 56: ...2 Installation 36 8 3 When Timeout due to RX_REQ not Negating ...

Page 135: ...2 Installation 115 16 2 Power Box Mass 4 2 Kg not including cable Unit mm ...

Page 136: ...2 Installation 116 16 3 Ready Lamp Unit Mass 0 5 Kg Unit mm ...