6-6

CHAPTER 6 TROUBLESHOOTING

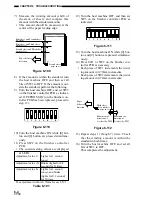

11) Change the settings of bits 6 through 8 on

DIPSW1 referring to Table 8-102 below.

• If the width adjustment is “0”,

The stitching position and the folding po-

sition match, requiring no change.

• If for “positive width adjustment,”

Set DIPSW1 so that the difference result-

ing from subtraction of the interval from

the appropriate setting in Table 8-102 is

provided.

For instance, if the DIPSW1 is currently

set to +2 and the interval is +1 mm, set

DIPSW1 to reflect -2.

• If for “negative width adjustment”

Set DIPSW1 so that the sum resulting

from addition of the interval from the ap-

propriate setting is provided.

For instance, if the DIPSW1 is currently

set to -1 and the interval is +0.5 mm, set

DIPSW1 to r1.

DIPSW1 bit settings

Settings

bit 6

bit 7

bit 8 (in units of 0.5 mm)

OFF

ON

ON

+3

OFF

ON

OFF

+2

OFF

OFF

ON

+1

OFF

OFF

OFF

0

ON

OFF

ON

−

1

ON

ON

OFF

−

2

ON

ON

ON

−

3

Do not touch the following:

bit 6

bit 7

bit 8

ON

OFF

OFF

Table 6-02

12) Set bits 1 through 4 on DIPSW1 to OFF.

2. Stitching Position (adjusting cen-

ter stitching)

Use the host machine adjustment mode

to perform the following:

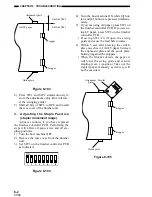

10) Measure the distance (L) between the

stitching position and the folding posi-

tion. Then, perform “positive width ad-

justment” or “negative width adjustment”

to suit the relationship between the stitch-

ing position and the folding position.

• If the stitching position is below the fold-

ing position, perform “positive width ad-

justment.”

• If the stitching position is above the fold-

ing position, perform “negative width

adjustment.”

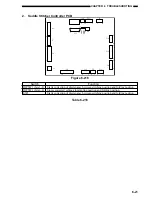

Mark

Mark

Folding position

Stitching position

Stitching position

Folding position

Positive Width Adjustment

Negative Width Adjustment

Unit: mm

Example: If L is 1 mm, provide “+1 mm”.

Unit: mm

Example: If L is 0.5 mm, provide “-0.5 mm”.

Figure 6-6

Содержание MJ-1027

Страница 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Страница 5: ...ii ...

Страница 9: ...vi ...

Страница 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Страница 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Страница 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Страница 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Страница 150: ...4 20 CHAPTER 4 MECHANICAL CONSTRUCTION 7 Remove the tension springs front 5 rear 6 Figure 4 216 Figure 4 217 5 6 ...

Страница 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Страница 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...