2-46

CHAPTER 2 FINISHER UNIT BASIC OPERATION

J.

Buffer Path Operation

1.

Outline

This machine is provided with a buffer paper path for continuously receiving paper from the

host machine during stapling and job offset operation on the stapling tray. A maximum of three

copies (three originals or more in the staple mode) are wrapped around the buffer roller. During this

time, job offset and stapling are performed on the stapling tray.

The following shows operation on the buffer paper path.

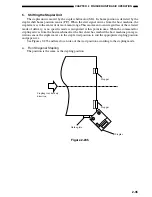

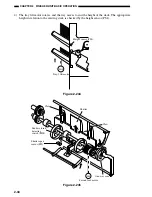

1) When the first sheet arrives, the buffer inlet solenoid (SL2) remains off. The first sheet enters

the buffer path.

OFF

SL2

First sheet

Buffer inlet solenoid

Figure 2-247

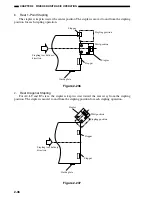

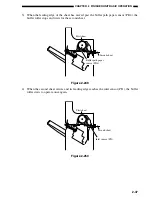

2) When the leading edge of the sheet has moved past the buffer path inlet paper sensor (PI17), the

buffer outlet solenoid (SL3) turns on so as to cause the sheet to wrap around the buffer roller.

ON

SL3

Buffer outlet

solenoid

Buffer path inlet paper

sensor (PI17)

Figure 2-248

Содержание MJ-1027

Страница 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Страница 5: ...ii ...

Страница 9: ...vi ...

Страница 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Страница 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Страница 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Страница 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Страница 150: ...4 20 CHAPTER 4 MECHANICAL CONSTRUCTION 7 Remove the tension springs front 5 rear 6 Figure 4 216 Figure 4 217 5 6 ...

Страница 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Страница 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...