6-4

CHAPTER 6 TROUBLESHOOTING

07/09

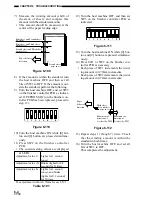

7) Measure the winding amount (shift) of

the stack of sheets, and compare this

amount with the standard amounts.

• This amount should be measured at the

center of the paper leading edge.

Third sheet

First sheet

Second sheet

Paper delivery

direction

First sheet and Second sheet:

0 ± 1mm

First sheet and Third sheet:

4mm or less

Second sheet and Third sheet:

4mm or less

Figure 6-09

8) If the amount is within the standard, turn

the host machine OFF, and then set all

bits of SW3 to OFF. If the amount is out-

side the standard, perform the following.

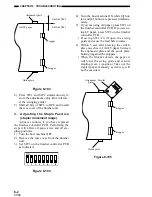

9) Turn the host machine OFF, and set SW3

on the finisher controller PCB as indicat

-

ed. If EEPROM (Q2) on the finisher con

-

troller PCB has been replaced, proceed to

step 12).

ON

1

2

3

4 5

6

7

8

Figure 6-0

10) Turn the host machine ON while [0] but-

ton and [8] button are pressed simultane-

ously.

11) Press SW2 on the finisher controller

PCB.

• The current setting values are displayed

at LED1.

Adjustment value 0 Lights for 1 second

(once)

Adjustment value +N Blinks (lights for 0.2

second) for N times.

Adjustment value -N Lights for 1 second

(once), and blinks

(lights for 0.2 second)

for N times.

The adjustment width is 0.72mm for each N=1.

Table 6-0

12) Turn the host machine OFF, and then set

SW3 on the finisher controller PCB as

indicated.

ON

1

2

3

4 5

6

7

8

Figure 6-

13) Turn the host machine ON while [0] but-

ton and [8] button are pressed simultane-

ously.

14) Press SW1 or SW2 on the finisher con

-

troller PCB as necessary.

• Each press of SW1 increments the wind-

ing amount in 0.72mm increments.

• Each press of SW2 decrements the wind-

ing amount in 0.72mm increments.

Third sheet

First sheet

Second sheet

Paper

delivery

direction

Movement of

direction of

1st sheet by SW1

Movement of

direction of

1st sheet by SW2

Figure 6-2

15) Repeat steps 1) though 7) twice. Check

that the winding amount is within the

standard in both times.

16) Turn the host machine OFF, and set all

bits of SW3 to OFF.

This completes the adjustment.

Содержание MJ-1027

Страница 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Страница 5: ...ii ...

Страница 9: ...vi ...

Страница 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Страница 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Страница 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Страница 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Страница 150: ...4 20 CHAPTER 4 MECHANICAL CONSTRUCTION 7 Remove the tension springs front 5 rear 6 Figure 4 216 Figure 4 217 5 6 ...

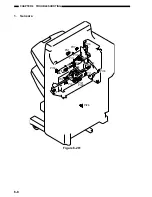

Страница 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Страница 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...