i

This Service Manual contains basic data and figures for the Finisher (MJ-1027)/Saddle

Stitch Finisher (MJ-1028) needed to service the machine in the field.

This manual comprises the following chapters:

Chapter 1

“General Description” introduces the finisher’s features, specifications, and

names of parts, and shows how to operate the finisher.

Chapter 2

“Finisher Unit Basic Operation” discusses the principles of operation used for

the finisher mechanical and electrical systems. It also explains the timing at

which these systems are operated.

Chapter 3

“Saddle Stitch Finisher Unit Basic Operation” discusses the principles of op-

eration used for the saddle stitcher unit’s mechanical and electrical systems.

It also explains the timing at which these systems are operated.

Chapter 4

“Mechanical System” discusses how the finisher is constructed mechanically,

and shows how it may be disassembled/assembled and adjusted.

Chapter 5

“Maintenance and Inspection” provides tables of periodically replaced parts

and consumables and durables, together with a scheduled servicing chart.

Chapter 6

“Troubleshooting” shows how to troubleshoot possible faults and gives electri-

cal parts arrangement diagrams, LED/check pin diagrams by PCB, and self

diagnosis tables.

“Appendix” contains diagrams showing tables of signals, overall circuit dia-

grams and tables of solvents/oils.

Descriptions regarding installation are not mentioned in this Service Manual as the

Finisher (MJ-1027)/Saddle Stitich Finisher (MJ-1028)’s packing boxes contain Installation

Procedures.

The descriptions in this Service Manual are subject to change without notice for prod-

uct improvement or other purposes, and major changes will be communicated in the form

of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins, and be able to identify and

isolate faults in the machine.

INTRODUCTION

Содержание MJ-1027

Страница 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Страница 5: ...ii ...

Страница 9: ...vi ...

Страница 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Страница 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Страница 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Страница 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Страница 150: ...4 20 CHAPTER 4 MECHANICAL CONSTRUCTION 7 Remove the tension springs front 5 rear 6 Figure 4 216 Figure 4 217 5 6 ...

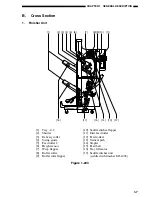

Страница 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Страница 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...