3-26

CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION

E.

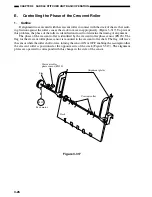

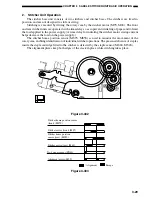

Controlling the Phase of the Crescent Roller

1.

Outline

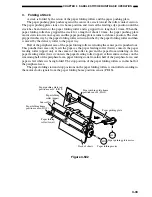

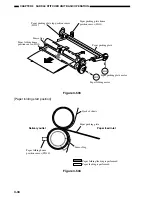

If alignment was executed with the crescent roller in contact with the stack of sheets, the result-

ing friction against the roller causes the stack to move inappropriately (Figure 3-317). To prevent

this problem, the phase of the roller is identified and used to determine the timing of alignment.

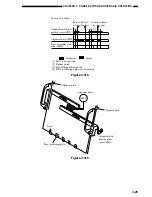

The phase of the crescent roller is identified by the crescent roller phase sensor (PI12S). The

flag for the crescent roller phase sensor is mounted to the crescent roller shaft. The flag will leave

the sensor while the roller shaft rotates, turning the sensor ON or OFF, enabling the assumption that

the crescent roller is positioned at the opposite side of the stack (Figure 3-319). The alignment

plates are operated to correspond with this change in the state of the sensor.

Crescent roller

phase sensor (PI12S)

Flag

Feed motor

Stack

Crescent roller

Alignment plates

M1S

Figure 3-317

Содержание MJ-1027

Страница 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Страница 5: ...ii ...

Страница 9: ...vi ...

Страница 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Страница 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Страница 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Страница 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Страница 150: ...4 20 CHAPTER 4 MECHANICAL CONSTRUCTION 7 Remove the tension springs front 5 rear 6 Figure 4 216 Figure 4 217 5 6 ...

Страница 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Страница 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...