24

Operating Instructions – MOVIDRIVE® MDR60A/61B

4

Installation notes

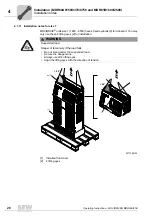

Installation (MDR60A0150/0370/0750 and MDR61B1600/2500)

•

Not permitted

: Mounting on vertical surfaces when the connection terminals are at

the top.

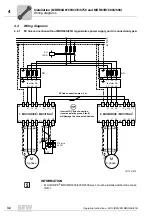

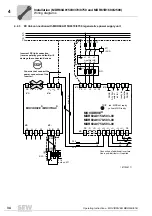

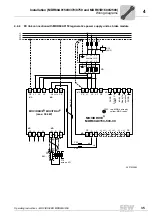

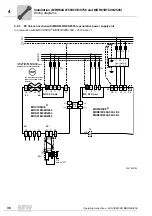

4.1.8

Connection of braking resistors

• Use

two tightly twisted leads or a 2-core shielded power cable

. Cable cross sec-

tion according to trip current I

F

of F16. The rated voltage of the cable must amount

to at least V

0

/V = 300 V / 500 V (in accordance with DIN VDE 0298).

• Protect the braking resistor (except for BW90-P52B) using a

bimetallic relay

(

→

wir-

ing diagram for basic unit, power section and brake). Set the

trip current

according

to the

technical data of the braking resistor

. SEW-EURODRIVE recommends

using an overcurrent relay from trip class 10 or 10A in accordance with EN 60947-4-

1.

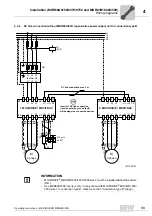

• For braking resistors of the

BW...-T / BW...-P

series, the

integrated temperature

switch/overcurrent relay can be connected using a 2-core shielded cable

as an

alternative

to a bimetallic relay.

•

Flat-type braking resistors

have internal thermal overload protection (fuse which

cannot be replaced). Install the

flat-type braking resistors

together with the appro-

priate

touch guard

.

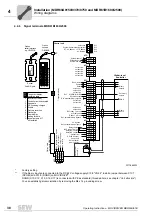

4.1.9

Operating braking resistors

• The connection leads to the braking resistors carry a

high pulsed DC voltage

during

rated operation.

WARNING

The surfaces of the braking resistors get very hot when the braking resistors are

loaded with P

N

.

Risk of burns and fire.

• Choose a suitable installation location. Braking resistors are usually mounted on

top of the control cabinet.

• Do not touch the braking resistors.

Содержание MDR60A

Страница 2: ...SEW EURODRIVE Driving the world...

Страница 145: ......

Страница 146: ......

Страница 147: ......