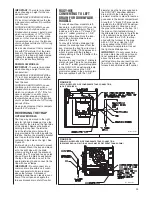

checked when converting the furnace

for LP operation. Figures 46 and 47

below show the incorrect way and the

correct way to install the jumper. The

jumper well is located next to the

adjustment well (with “+” and “–” text

and two-headed arrow) and will be

covered by a sticker or label. To con-

vert to LP the label over the jumper

well will need to be removed.

SETTING GAS PRESSURE

A properly calibrated pressure gauge

or U-Tube manometer is required for

accurate gas pressure measure-

ments.

ELEVATIONS ABOVE 2000 FT

REQUIRE THAT THE FURNACE

INPUT RATING BE ADJUSTED

AND THAT THE SIZE OF THE

BURNER ORIFICES BE RE-CAL-

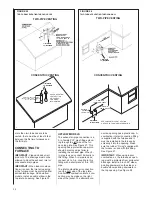

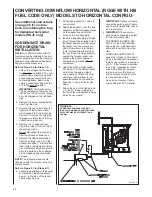

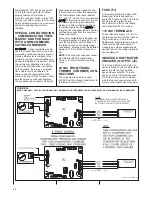

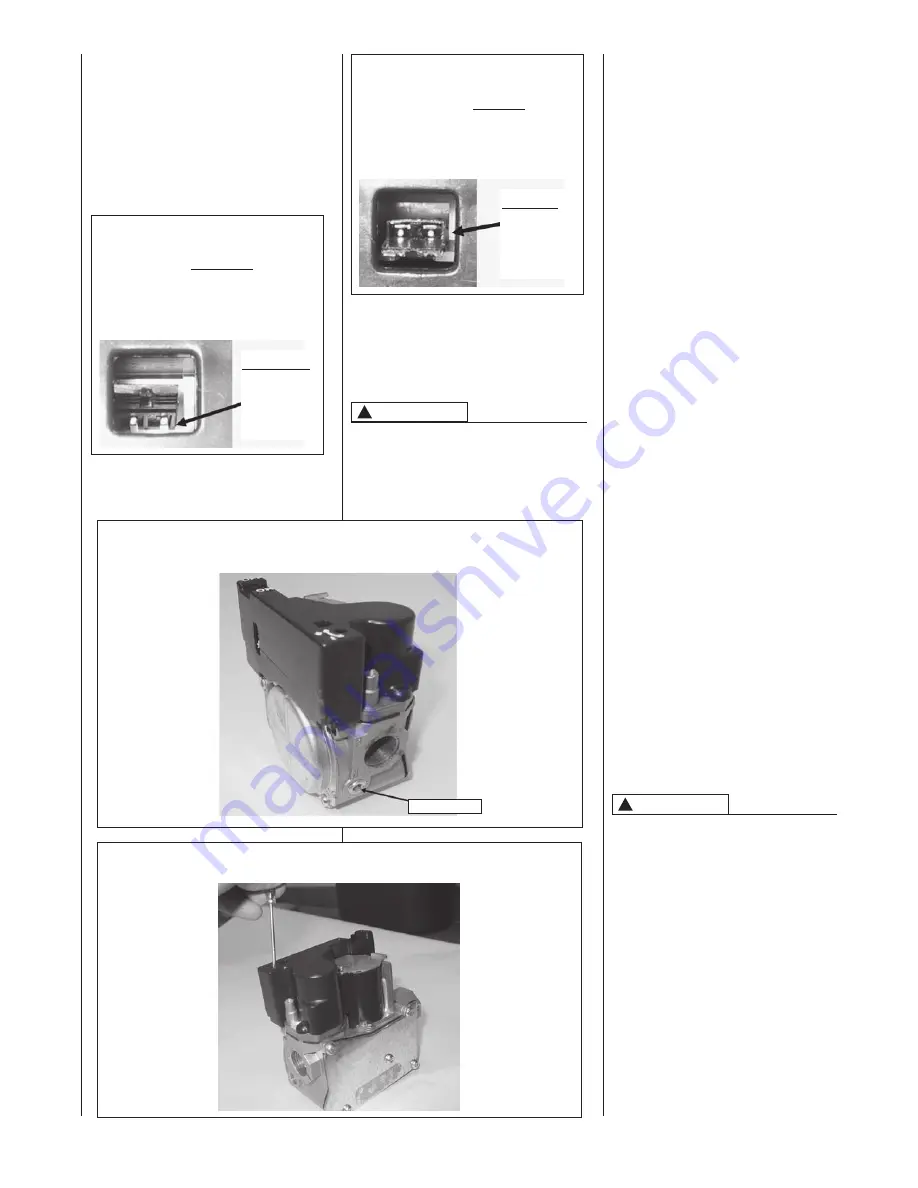

FIGURE 48

SERVO-CONTROLLED GAS VALVE MANIFOLD PRESSURE TAP LOCATION

(FUEL CODE: HA OR HB)

CULATED BASED ON ELEVATION

AND GAS HEATING VALUE. THE

BURNER ORIFICES MAY (OR MAY

NOT) NEED TO BE CHANGED. SEE

THE SECTION TITLED “HIGH ALTI-

TUDE INSTALLATIONS” OF THIS

BOOK FOR INSTRUCTIONS.

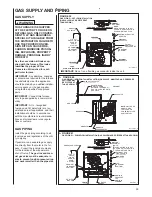

Supply Gas Pressure Measure-

ment.

1. With gas shut off to the furnace

at the manual gas valve outside

the unit, remove the line

pressure tap plug on the gas

valve. See Figure 48.

2. Connect a U-Tube manometer to

the pressure tap.

3. Turn on the gas supply and

operate the furnace at 100% and

all other gas-fired units on the

same gas line as the furnace.

4. Note or adjust the supply-line

pressure to give:

A. 5" - 10.5" w.c. for natural gas.

B. 11" - 13" w.c. for LP gas.

5. Shut off the gas at the manual

gas valve and remove the

U-Tube manometer.

6. Replace the supply-line pressure

tap plug before turning on the

gas.

7. Check unit for leaks.

If the supply-line pressure is above

these ranges, install an in-line gas

regulator to the furnace for natural

gas units. With LP gas, have the LP

supplier reduce the supply-line pres-

sure at the regulator.

If supply-line pressure is below these

ranges, either remove any restrictions

in the gas supply piping or enlarge

the gas pipe. See Tables 8 and 9.

With LP gas, have the LP supplier

adjust the su

pply-line pressure at the

regulator.

ELEVATIONS ABOVE 2000 FT

REQUIRE THAT THE FURNACE

INPUT RATING BE ADJUSTED

AND THAT THE SIZE OF THE

BURNER ORIFICES BE RE-CAL-

CULATED BASED ON ELEVATION

AND GAS HEATING VALUE. THE

BURNER ORIFICES MAY (OR MAY

NOT) NEED TO BE CHANGED. SEE

THE SECTION TITLED “HIGH ALTI-

TUDE INSTALLATIONS” OF THIS

BOOK FOR INSTRUCTIONS.

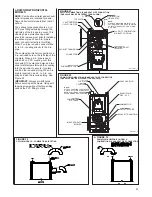

FIGURE 49

SERVO CONTROLLED GAS VALVE PRESSURE ADJUSTMENT (FUEL CODE: HA OR HB)

CAUTION

!

CAUTION

!

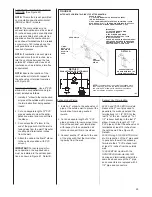

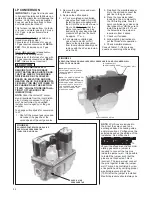

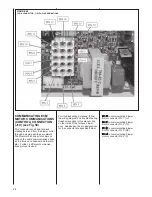

FIGURE 46

LP JUMPER INSTALLED ON SERVO MODU-

LATING GAS VALVE WITH PINS NOT CON-

NECTED. THIS IS INCORRECT. MAKE

SURE THAT THE JUMPER CONNECTS THE

TWO PINS TOGETHER AND VERIFY MANI-

FOLD GAS PRESSURE AT HIGH FIRE TO

MAKE SURE THE VALVE IS PROPERLY

CONVERTED FOR LP GAS

JUMPER

IMPROPERLY

INSTALLED.

NOTE THAT

PINS ARE

NOT CON-

NECTED.

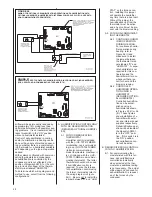

FIGURE 47

LP JUMPER INSTALLED ON SERVO MODU-

LATING GAS VALVE WITH PINS PROPERLY

CONNECTED. THIS IS CORRECT. MAKE

SURE THAT THE JUMPER CONNECTS THE

TWO PINS TOGETHER AND VERIFY MANI-

FOLD GAS PRESSURE AT HIGH FIRE TO

MAKE SURE THAT THE VALVE IS PROPER-

LY CONVERTED FOR LP GAS

JUMPER

PROPERLY

INSTALLED.

NOTE THAT

PINS ARE

CONNECTED.

MANIFOLD TAP

43

NOTE:

The adjust-

ment wheel will not

stop rotating when

it hits the maximum

or minimum posi-

tion. Instead, it will

continue to rotate

to the opposite

adjustment. Use

the letters on the

wheel as a guide.

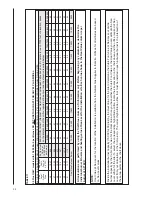

Содержание RGFE

Страница 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 101: ...101 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED when the inducer is energized at low ...

Страница 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 106: ...106 FIGURE 83 WIRING DIAGRAM STEPPER MODULATING GAS VALVE FUEL CODE HA OR HB FURNACE MODEL IS RGFE RGGE ...

Страница 107: ...107 FIGURE 84 WIRING DIAGRAM SOLENOID CONTROLLED GAS VALVE FUEL CODE HG OR HH FURNACE MODEL RGGE RGFE RGJF ...