122

However, after a two-hour period,

this will change and the thermostat

will take as long as five minutes for

every degree F to change the dis-

play. Therefore, for example a rapid

change of five degrees in room tem-

perature will not be correctly indicat-

ed at the thermostat for (up to) 25

minutes. This is done to buffer the

thermostat against rapid and insignif-

icant swings in temperature caused

by briefly opening a door or window.

This operation prevents excessive

cycling of the thermostat and is a

feature used in all modern ther-

mostats.

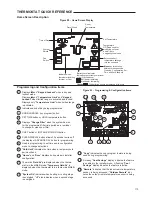

COMMUNICATING THERMOSTATS

COMMUNICATING THER-

MOSTATS

The modulating furnace is capable of

communicating with a thermostat and

condenser to improve cooling and heat-

pump airflow, displaying active faults

and active furnace information at the

thermostat and improved diagnostics

and troubleshooting.

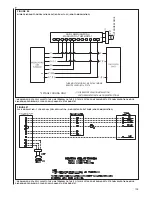

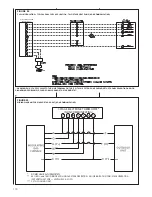

WIRING A FURNACE FOR

COMMUNICATIONS.

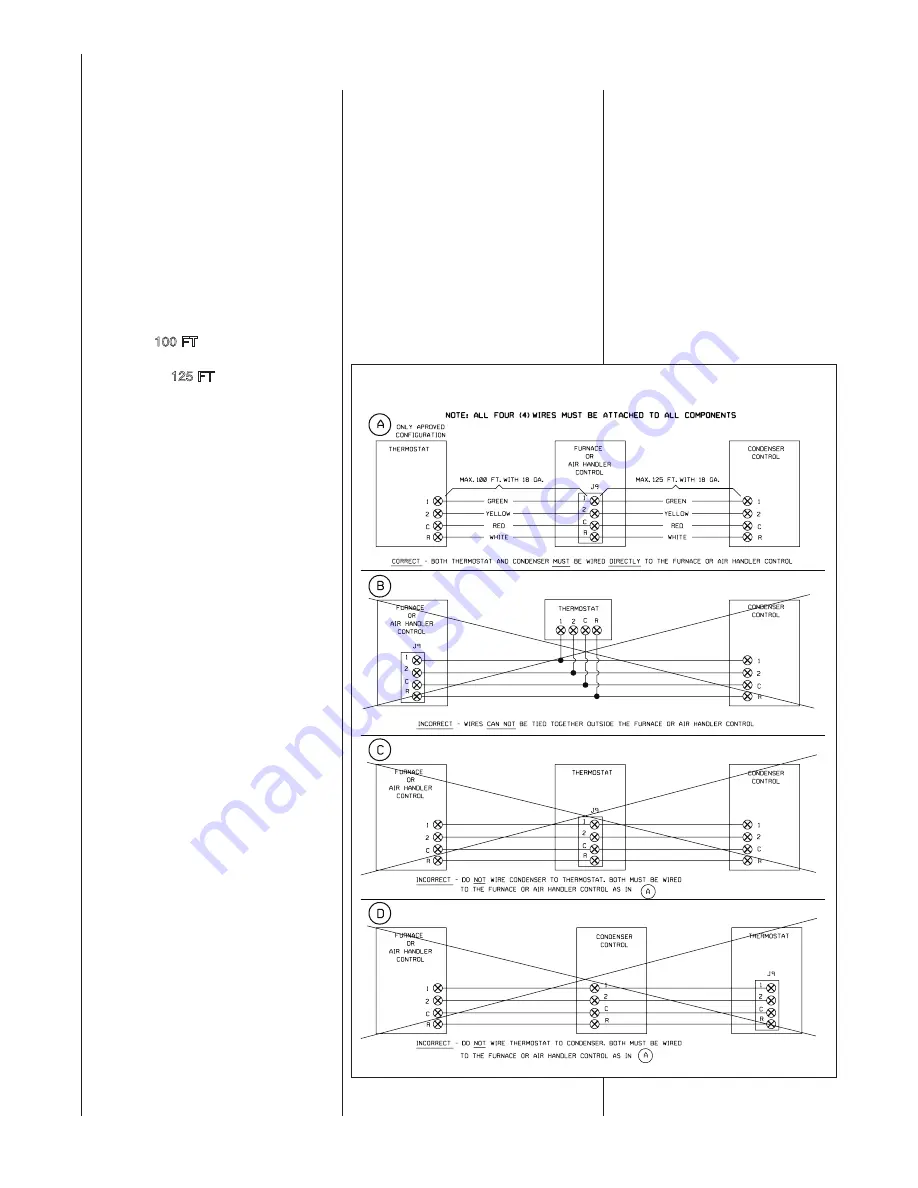

MAXIMUM COMMUNICATING WIRE

LENGTHS (1, 2, R & C)

Max Wire Length – Thermostat to

Furnace = 100 FT @ 18 AWG*

Max Wire Length – Furnace to

Condenser = 125 FT @ 18 AWG*

Notes:

1. When using twisted pairs, be sure the

wires connected to pins labeled “1”

(recommended wire color = green)

and “2” (recommended wire color =

yellow) are a twisted pair.

2. Wires may be solid or stranded.

3. *Wire gage smaller than 18 AWG is

not approved or recommended for

this application.

4. When using existing wire from a pre-

vious installation, be sure to trim the

tip of the wire back past the insulation

and strip a small amount of insulation

from the wire to expose clean new

copper for the communicating con-

nections. Fresh copper must be

exposed when making the communi-

cating connections or communications

may not be properly established.

Figures 96 through 97 below are wiring

diagrams for connecting the furnace to

an approved ClimateTalk communicat-

ing thermostat and approved Rheem or

Ruud communicating condenser.

The only approved configuration for

fully communicating systems is to install

dedicated wires directly from the fur-

nace to the thermostat and a separate

set of dedicated wires directly from the

furnace to the condenser. Note: The

only approved configuration for systems

with a communicating condenser

requires that four dedicated wires (1, 2,

R and C) be installed from the furnace

to the condenser.

TWO NOTES ABOUT COM-

MUNICATING THER-

MOSTATS

1. When power to the thermostat has

been reset and/or the batteries are

replaced, the thermostat will respond

quickly to changes in room tempera-

ture as indicated by the room tem-

perature displayed at the thermostat.

2. For dual-fuel systems, once the

thermostat has switched over to

auxiliary heat (e.g. gas heat), sub-

sequent heat calls may also

immediatel

y begin with auxiliary

heat regardless of the dual-fuel

changeover point and the actual

outdoor temperature or the differ-

ence between room temperatures

and setpoint. This is true as long

as the subsequent heat call is

within 12 minutes or less of end

of the previous heat call. The

actual time between heat calls

that will cause this operation

varies but should not exceed 12

minutes.

FIGURE 96

WIRING DIAGRAM – COMMUNICATING CONFIGURATION

A-1114-01

Содержание RGFE

Страница 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 101: ...101 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED when the inducer is energized at low ...

Страница 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

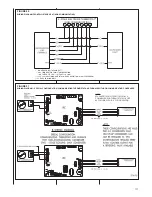

Страница 106: ...106 FIGURE 83 WIRING DIAGRAM STEPPER MODULATING GAS VALVE FUEL CODE HA OR HB FURNACE MODEL IS RGFE RGGE ...

Страница 107: ...107 FIGURE 84 WIRING DIAGRAM SOLENOID CONTROLLED GAS VALVE FUEL CODE HG OR HH FURNACE MODEL RGGE RGFE RGJF ...