➤

SERVO GAS VALVE (FUEL

➤

CODE: HA OR HB) MANIFOLD

➤

GAS PRESSURE

➤

MEASUREMENT/ADJUSTMENT.

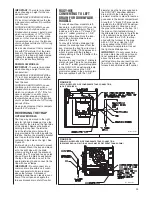

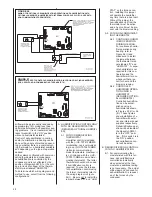

1. With the gas to the unit shut off at

the manual gas valve, remove the

outlet pressure tap plug in the gas

valve. See Figure 48.

2. Connect the positive pressure

hose from a manometer to the

pressure tap.

3. Note the manifold gas pressure to

be:

A. 3.5" w.c. (±.3) for natural gas .

B. 10.0" w.c. ( ±.5) for LP gas.

NOTE:

Make sure the unit is oper-

ating at maximum heating capacity

(100%) before adjusting the mani-

fold pressure.

4. To adjust the pressure regulator,

insert a small slotted screwdriver

into the opening at the top of the

valve (see Figure 49).

NOTE:

Only small variations in gas

pressure should be made by

adjusting the pressure regulator.

NOTE:

Allow up to 5 seconds for

each change in manifold pressure.

5. Turn the adjustm

ent screw clock-

wise to increase pressure, or coun-

terclockwise to decrease pressure.

See Figure 49.

6. Check manifold gas pressure.

7. Repeat step 5 & 6 if needed.

8. Securely replace the regulator cap.

NOTE:

Shut off gas at the manual

gas valve and remove the U-Tube

manometer.

9. Replace the manifold pressure tap

plug before turning on

the gas.

10. Check unit for leaks.

➤

SOLENOID GAS VALVE (FUEL

➤

CODE: HG OR HH) MANIFOLD

➤

GAS PRESSURE

➤

MEASUREMENT.

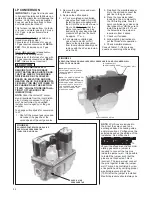

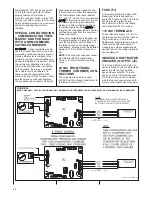

1. With the gas to the unit shut off

at the manual gas valve, remove

the outlet pressure tap plug in

the gas valve. See Figure 50.

2. Connect the positive pressure

hose from a manometer to the

pressure tap.

3. Note the manifold gas pressure

to be:

A. 3.5" w.c. (±.3) for natural

gas .

B. 10.0" w.c. ( ±.5) for LP gas.

4. To adjust the pressure regulator,

remove the regulator cap.

NOTE:

Only small variations in

gas pressure should be made by

adjusting the pressure regulator.

5. Turn the adjustment screw, using

a

3

⁄

32

" allen wrench, clockwise to

increase pressure, or counter-

clockwise to decrease pressure.

See Figure 51.

6. Check manifold gas pressure.

7. Repeat step 5 & 6 if needed.

8. Securely replace the regulator

cap.

NOTE:

Shut off gas at the manu-

al gas valve and remove the U-

Tube manometer.

9. Replace the manifold pressure

tap plug before turning on

the gas.

10. Check unit for leaks.

NOTE:

Do not use gas valve pres-

sure adjustment as a means to

adjust temperature rise. The blower

motor will change speed to maintain

a reasonably constant temperature

rise.

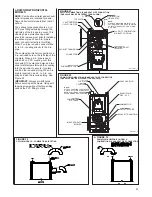

FIGURE 50

SOLENOID CONTROLLED MANIFOLD PRESSURE TAP LOCATION (FUEL CODE HA OR HB)

OUTLET MANIFOLD PRESSURE TAP

FIGURE 51

SOLENOID CONTROLLED GAS VALVE PRESSURE ADJUSTMENT (3/32" ALLEN WRENCH)

(FUEL CODE HH OR HG)

REGULATOR CAP

44

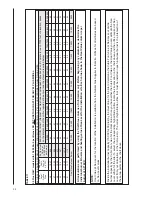

Содержание RGFE

Страница 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 101: ...101 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED when the inducer is energized at low ...

Страница 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

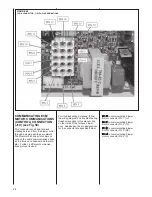

Страница 106: ...106 FIGURE 83 WIRING DIAGRAM STEPPER MODULATING GAS VALVE FUEL CODE HA OR HB FURNACE MODEL IS RGFE RGGE ...

Страница 107: ...107 FIGURE 84 WIRING DIAGRAM SOLENOID CONTROLLED GAS VALVE FUEL CODE HG OR HH FURNACE MODEL RGGE RGFE RGJF ...