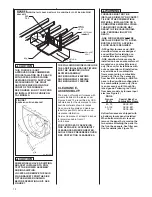

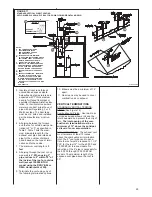

SUPPLY AIR SENSOR

Each furnace comes shipped from the

factory with a supply air sensor. Install

the sensor, in the supply air plenum

trunk, with two, field supplied, #8 sheet

metal screws, using the following guide-

lines:

1. 12” downstream of the evaporator

coil, if installed.

2. If no evaporator coil is used, locate

the sensor out of direct line-of-site

of the heat exchanger and

not clos-

er than 18” downstream of the fur-

nace outlet.

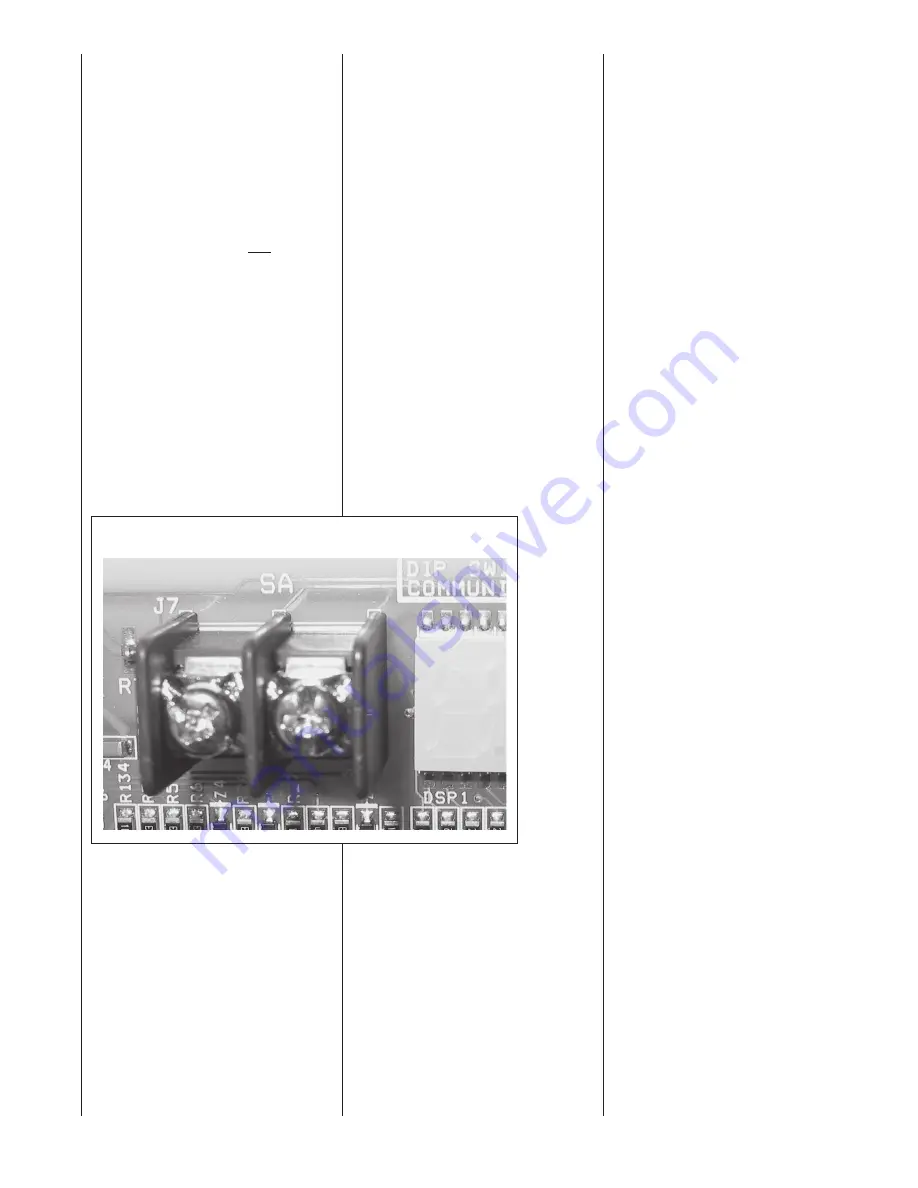

3. Attach the supply air sensor wires

onto the terminals marked “SA

Sensor” on the integrated furnace

control board (See Figure 13).

4. Do not extend the supply-air sensor

wire.

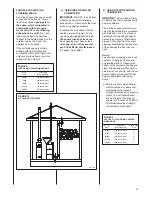

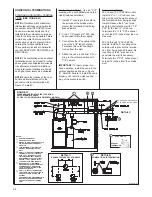

NOTE:

Improper placement of the

supply air sensor can adversely

affect furnace temperature rise.

NOTE:

In downflow circumstances

where building construction does not

allow for the placement of the sensor to

fall within these parameters, the supply

air sensor should not be connected.

This means that the furnace will run

under default parameters. When run-

ning under default parameters, the “82”

code will appear for 90 seconds. After

that, the fault code will be stored in the

control board’s memory and will show

only upon power cycling. Default airflow

parameters can be manually adjusted.

See section discussing Integrated

Furnace Control (IFC) board in this

manual.

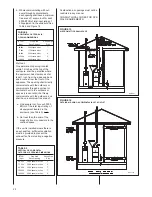

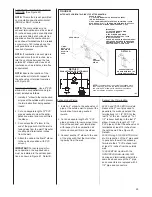

For communicating systems, the

supply air sensor input can be turned

off so that a fault code will not be

displayed at all. This can be done in

the furnace setup menu of a commu-

nicating thermostat. See the section

of this manual titled Communicating

Systems under sub-section titled

Furnace User Menus (Setup).

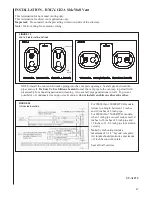

FIGURE 13

SUPPLY AIR SENSOR TERMINALS

17

Содержание RGFE

Страница 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 101: ...101 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED when the inducer is energized at low ...

Страница 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Страница 106: ...106 FIGURE 83 WIRING DIAGRAM STEPPER MODULATING GAS VALVE FUEL CODE HA OR HB FURNACE MODEL IS RGFE RGGE ...

Страница 107: ...107 FIGURE 84 WIRING DIAGRAM SOLENOID CONTROLLED GAS VALVE FUEL CODE HG OR HH FURNACE MODEL RGGE RGFE RGJF ...