Loosen the M3 screw on the probe holder to make adjustments. Gently push or pull the

sensor to adjust the height and tighten the M3 screw again.

Then re-run Calibrate Z followed

by the First layer calibration again.

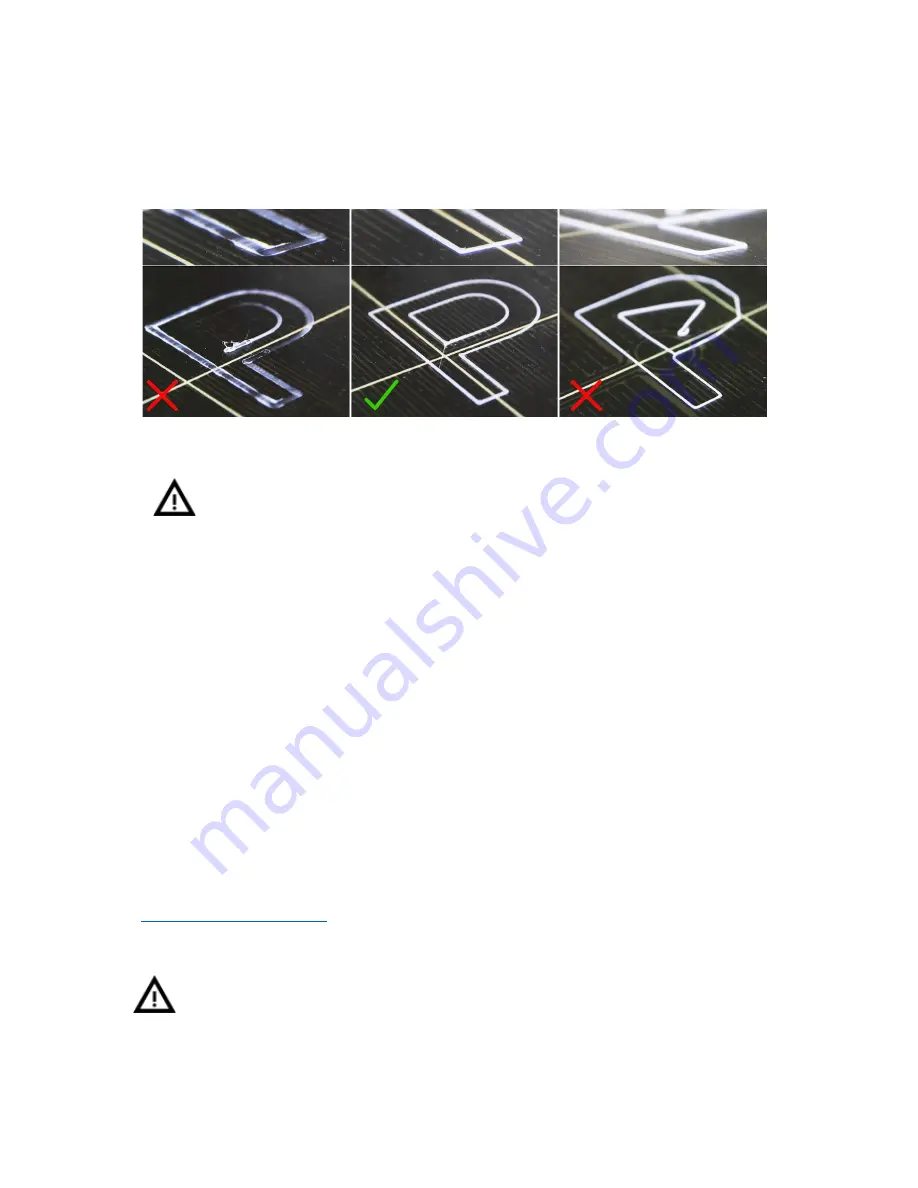

Pict. 11 - The properly-tuned first layer

When printing the extruder motor can reach up to 55°C, that is completely

fine

, they are designed to run up to 100 °C. It needs to work harder compared to

the MK2 as the Bondtech gear is larger.

6.2.9.1 Bed level correction

Bed level correction is an advanced feature that is designed to allow advanced users to

correct for the slightest imperfections in the first layer. This feature can be found in

LCD Menu - Calibration

-

Bed level correction.

For example, if the first layer seems to be

ever so slightly more squished on the right side, you can virtually raise the nozzle by

+20

microns on the right side. Settings are available for Left, Right, Front and Back. The limit is

+-50 microns and even +-20 microns can make a huge difference. When you are using this

function, do small incremental changes. A negative value will act as lowering the bed in the

selected direction.

6.2.10 Fine tuning the first layer

6.2.10.1 Print Prusa logo

After finishing the calibration gcode, it is a good idea to print a simple object. The Prusa logo

from the supplied SD card is a great example. The

Live adjust Z

function (described in

6.2.9. First layer calibration

) works during every print, so you can fine tune at any point. You

can see the properly-tuned first layer in Pict. 12.

Calibration might be slightly different for different steel print sheets as the coating

thickness varies. It is a good practice to check the first layer and adjust accordingly

with

Live adjust Z

when switching between different types of steel sheets.

24

Содержание i3 MK2.5

Страница 1: ......

Страница 9: ...Pict 1 Original Prusa i3 MK2 5 printer upgrade Pict 2 Description of Original Prusa i3 MK2 5 9 ...

Страница 64: ...Pict 40 Nozzle change 64 ...