4–7

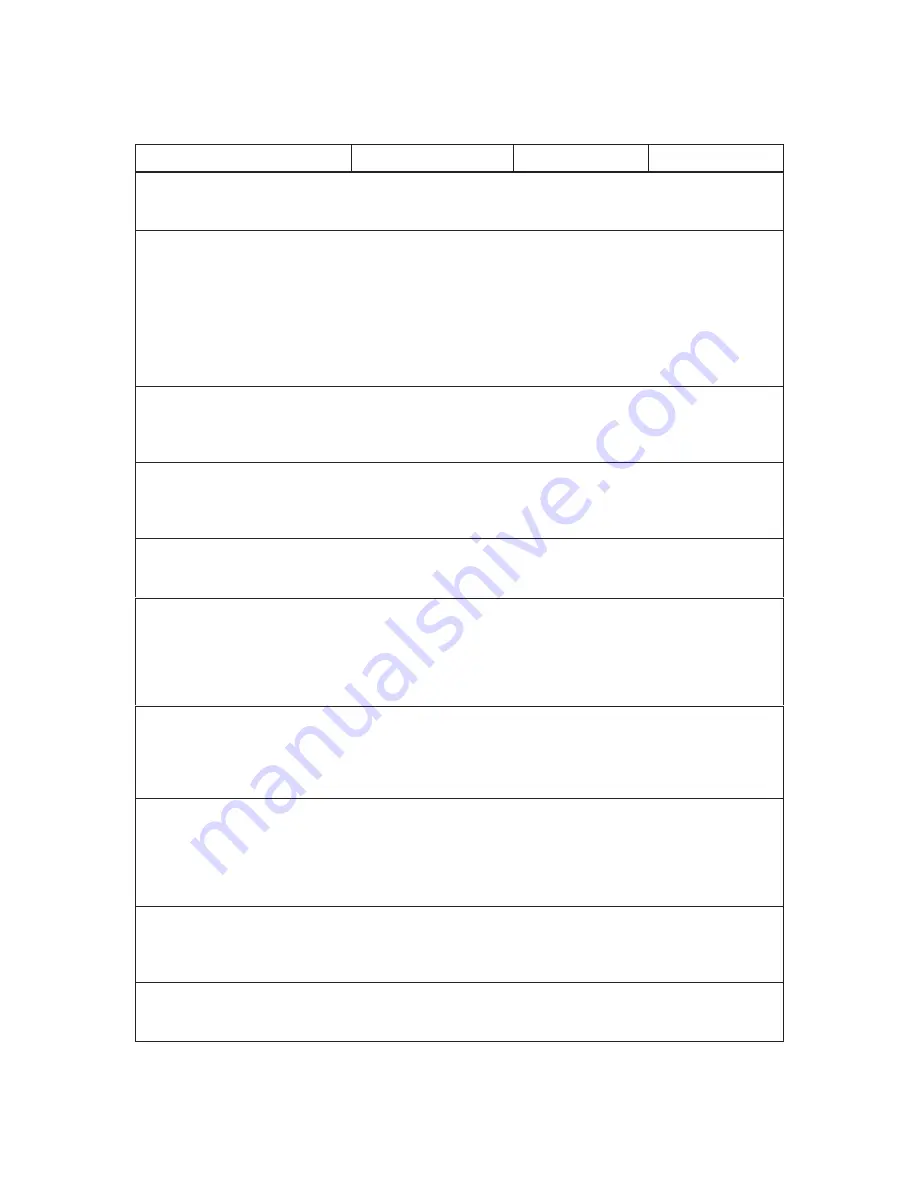

Troubleshooting

PAPER JAM

Instruction

Indication

Yes

No

1.

Inspect paper path for

bunched, torn, folded paper

or labels.

Paper path is clear.

Step 2.

Remove paper

and go to step 2.

2.

Inspect the narrow

passageway between the

face of the platen and the

ribbon mask for bits of torn

paper or ribbon lint. Check

the holes in the ribbon mask

surrounding each hammer

tip.

Debris found.

Gently remove

paper or lint

particles with a

wooden stick or

pair of tweezers.

CAUTION: Do not

pry or apply force

to the hammer

tips. Go to step 3.

Step 3.

3.

Check that the ribbon mask

has not been deformed in

such a way as to block the

paper path.

Ribbon mask damaged

or bent.

Replace the

hammer bank

cover assembly.

Go to step 4.

Step 4.

4.

Load paper. Do some line

feeds and run a diagnostic

self–test (page 4–14).

PAPER JAM message.

Clean the paper

motion detector

with cotton swab.

Go to step 7.

Return printer to

normal operation.

5.

Set the paper motion sensor

fault setting to DISABLE. See

the

P9012 User’s Manual.

PAPER JAM message.

Return printer to

normal operation.

6.

Check paper feeding as the

printer prints.

PAPER JAM message.

Check the tractors

and spring behind

the tractor door.

Replace the

mechanism driver

(page 6–72).

Return printer to

normal operation.

7.

Run a diagnostic self–test

(page 4–14).

PAPER JAM message.

Replace paper

motion sensor

assembly (page

6–62). Go to step

8.

Return printer to

normal operation.

8.

Check the platen gap

adjustment (5–18).

Platen gap incorrect.

Adjust the platen

gap until it is

within spec and

the message

disappears. Go to

step 9.

Return printer to

normal operation.

9.

Check for damage to the

paper feed motor or belt.

Paper feed motor or

belt damaged.

Replace the paper

feed motor (6–56)

or belt (6–52). Go

to step 10.

Return printer to

normal operation.

10. Run a diagnostic self–test

(page 4–14).

PAPER JAM message.

Replace the MCU

PCBA (page

6–72).

Return printer to

normal operation.

Содержание P9012

Страница 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Страница 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Страница 53: ...2 35 Principles of Operation PAPER FEED MOTOR TRACTORS PAPER TRANSPORT Figure 2 26 Paper Feed Components...

Страница 58: ...2 40 Principles of Operation...

Страница 84: ...4 18 Troubleshooting...

Страница 107: ...5 23 Alignments and Adjustments 1 Screw 2 MPU Arm 1 2 Figure 5 9 Magnetic Pickup Phasing Adjustment...

Страница 118: ...5 34 Alignments and Adjustments...

Страница 203: ...6 85 Replacement Procedures This page intentionally left blank...

Страница 214: ...6 96 Replacement Procedures...

Страница 217: ...A 3 Power Paper Stacker Maintenance Printer Rear Power Paper Stacker Figure A 1 Power Paper Stacker...

Страница 236: ...A 22 Power Paper Stacker Maintenance...

Страница 246: ...D 2 Torque Table...

Страница 254: ...Index 6...

Страница 255: ......

Страница 256: ...132305 001 Rev E...