6–20

Replacement Procedures

Installation

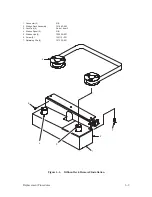

1. Engage the shuttle assembly over the alignment pin and slide the left end

of the shuttle toward the rear of the printer.

2. Install and hand tighten two screws (11) and lockwashers (12) and one

shoulder screw (13) and lockwasher (14).

3. Torque the two screws and one shoulder screw to 40 in–lbs.

CAUTION

Do not overtighten these screws. Over–tightening will strip the threads

in the casting, and the casting will require replacement.

4. Working from left to right, connect the coil connectors.

5. Install the dust barrier block, two screws (7), and lockwashers (8).

Torque screws to 8 in–lbs.

CAUTION

Take care. Barrier block screws (7) are easily damaged.

6. Install the gasket, cam front cover plate, and six screws (4).

7. Install the cam cover and tighten two captive screws (2).

8. Install the ribbon deck as described on page 6–8. Set the shuttle preload

as described on page 5–6 of Chapter 5, Alignments and Adjustments.

Содержание P9012

Страница 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Страница 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Страница 53: ...2 35 Principles of Operation PAPER FEED MOTOR TRACTORS PAPER TRANSPORT Figure 2 26 Paper Feed Components...

Страница 58: ...2 40 Principles of Operation...

Страница 84: ...4 18 Troubleshooting...

Страница 107: ...5 23 Alignments and Adjustments 1 Screw 2 MPU Arm 1 2 Figure 5 9 Magnetic Pickup Phasing Adjustment...

Страница 118: ...5 34 Alignments and Adjustments...

Страница 203: ...6 85 Replacement Procedures This page intentionally left blank...

Страница 214: ...6 96 Replacement Procedures...

Страница 217: ...A 3 Power Paper Stacker Maintenance Printer Rear Power Paper Stacker Figure A 1 Power Paper Stacker...

Страница 236: ...A 22 Power Paper Stacker Maintenance...

Страница 246: ...D 2 Torque Table...

Страница 254: ...Index 6...

Страница 255: ......

Страница 256: ...132305 001 Rev E...