49

EN

Symptoms

Location to investigate

Solution

Stop during the screw

fastening rotation

Aren't burrs, dregs, or particles caught in

the screw hole or screw part?

Check the screw or workpiece.

Is the tapping screw tightened?

It is possible that the setting torque was exceeded

when tightening the screw (before seating).

Check the screw fastening state, and raise the

setting torque.

Have you attached a heavy jig or a jig

having a large radius at the bit tip?

It is possible that the jig inertial force has boosted

the motor current, to attain the setting torque.

Either review the jig (make it lighter, make it

smaller), or boost the setting torque.

Can it be stopped by idling (free rotation

state)?

It is possible that some sort of load can be applied

to the bit area, to boost the motor current, and

attain the setting torque.

Either cancel the load applied to the bit area, or

boost the setting torque.

Is a load applied to the bit area during

screw tightening?

The output torque

is low

Screws cannot be

tightened

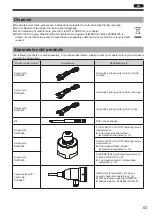

Are you correctly combining the measuring

devices for measurement?

In addition, are the types of joint washers

(white rubber, black rubber, metal)

incorporated into screw joints, or the

incorporated sequence, correct?

Use a combination of NITTO KOHKI designated

measuring devices for measurement. (p. 8)

Check whether the screw joints are correct, and

perform measurement. (p. 10)

Has the permanent set in fatigue, cracks,

deformation, and hardening occurred in the

joint washers (white rubber, black rubber,

metal) incorporated into screw joints?

(p. 10)

In cases where changes have occurred in the

rubber, there is a need to replace with new joint

washer parts.

Has the output torque changed?

The output torque changes over time.

Regularly check the output torque, and adjust the

setting torque. (p. 11)

Did you check the correlation between

the output torque occurred on screws

and the output torque measured using a

measurement device?

The output torque occurred on screws and the

output torque measured by the measurement

device are different.

Adjust the output torque according to the screw

fastening conditions. (p. 11)

Are there differences in the screw

fastening operation methods (operator,

force for handling or pressing the electric

screwdriver, fixing method, etc.)?

Torque conveyed to the motor current or screw

changes depending on the operations method.

Perform the screw tightening under fixed

operation conditions.

Is the bit worn out?

When the bit is worn out, it becomes difficult to

convey the torque to screws. Replace the bit.

Are you tightening while crushing a part

between the screws?

Has regression loosening occurred?

Torque may not be transmitted. Crush the part

once and then tighten the screw.

Has axial force occurred to the screw?

Without axial force, even though the output torque

is increased, screws are not tightened. Review the

screw fastening conditions.

Has initial loosening occurred?

Initial loosening occurs as a result of permanent

set in fatigue when fine irregularities such as

surface roughness are lost over time after the

screw is tightened or outside force is applied.

Remove the screw and tighten it again.

Has the permanent set in fatigue occurred

due to permanent deformation of sealing

material such as the gasket?

Carefully check the screw fastening conditions

and set the output torque.

Has the temperature surrounding the

electric screwdriver, screw, or workpiece

changed?

Change in temperature can deform the workpiece,

stretch or loosen the screws, or cause changes in

the electric screwdriver characteristics.

Review the screw fastening conditions and

process.

Are there occurrence or impressions of

vibrations or external force?

Loosening of screw occurs if no measures are

taken for vibration or outside force.

Take appropriate loosening prevention measures,

as necessary.

TV07783-1_DLV10C_en.indb 49

2017/06/27 17:41:42